Overview

This project started as a way to bridge hardware + software through a real, iterative build. The core goal: a reliable hexapod platform that’s easy to tweak mechanically (parametric CAD), easy to assemble, and easy to maintain.

Key idea

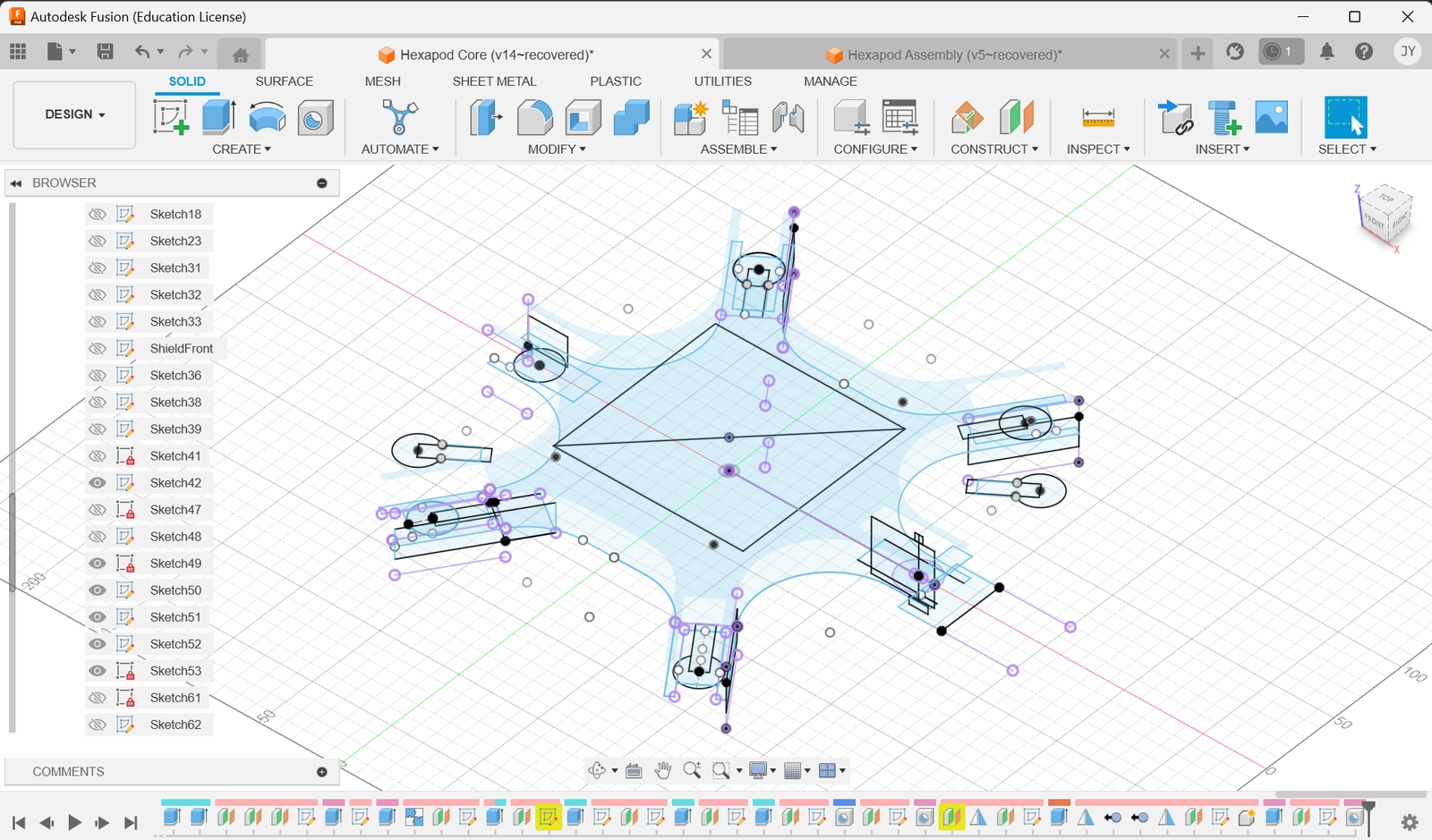

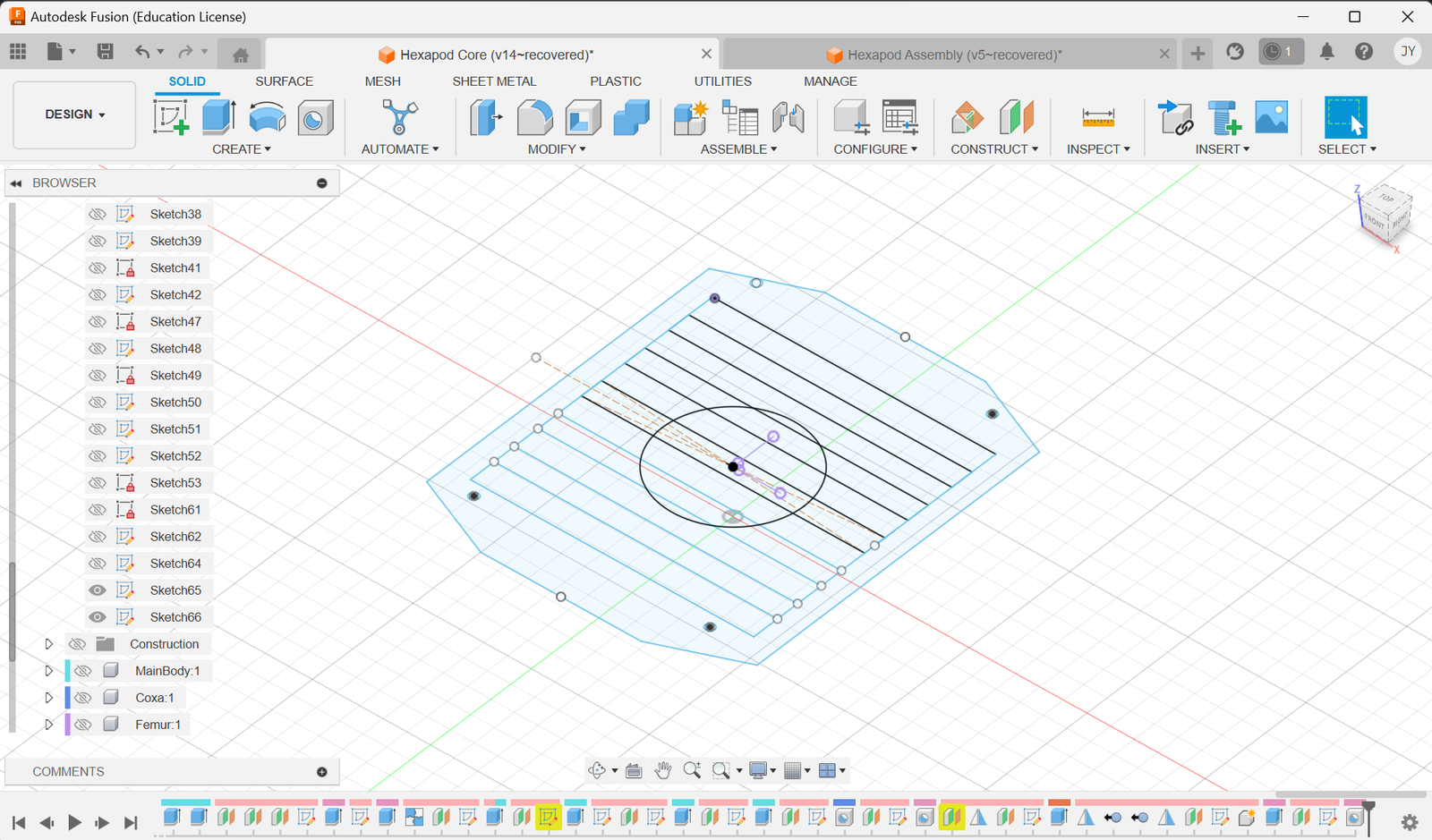

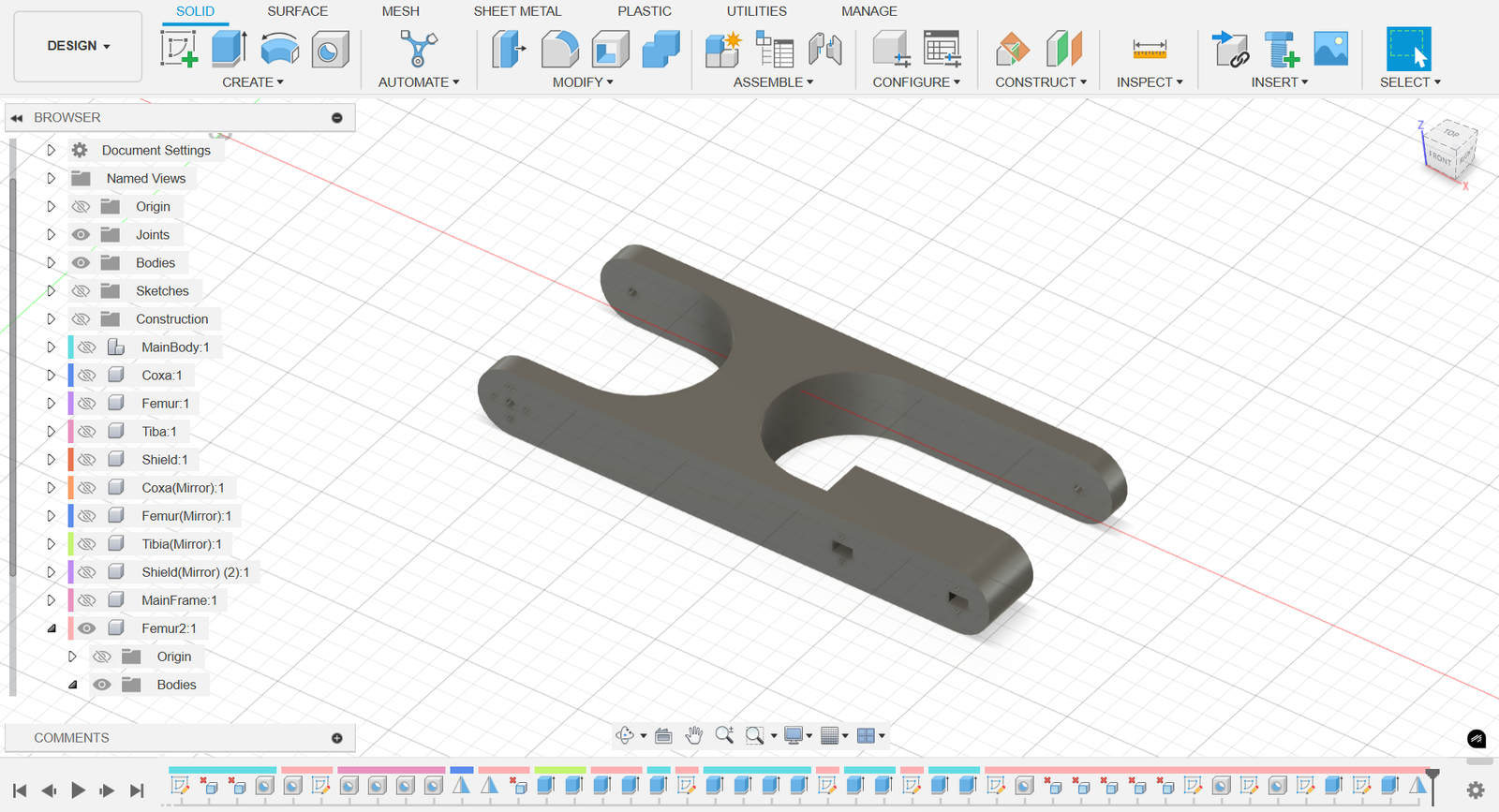

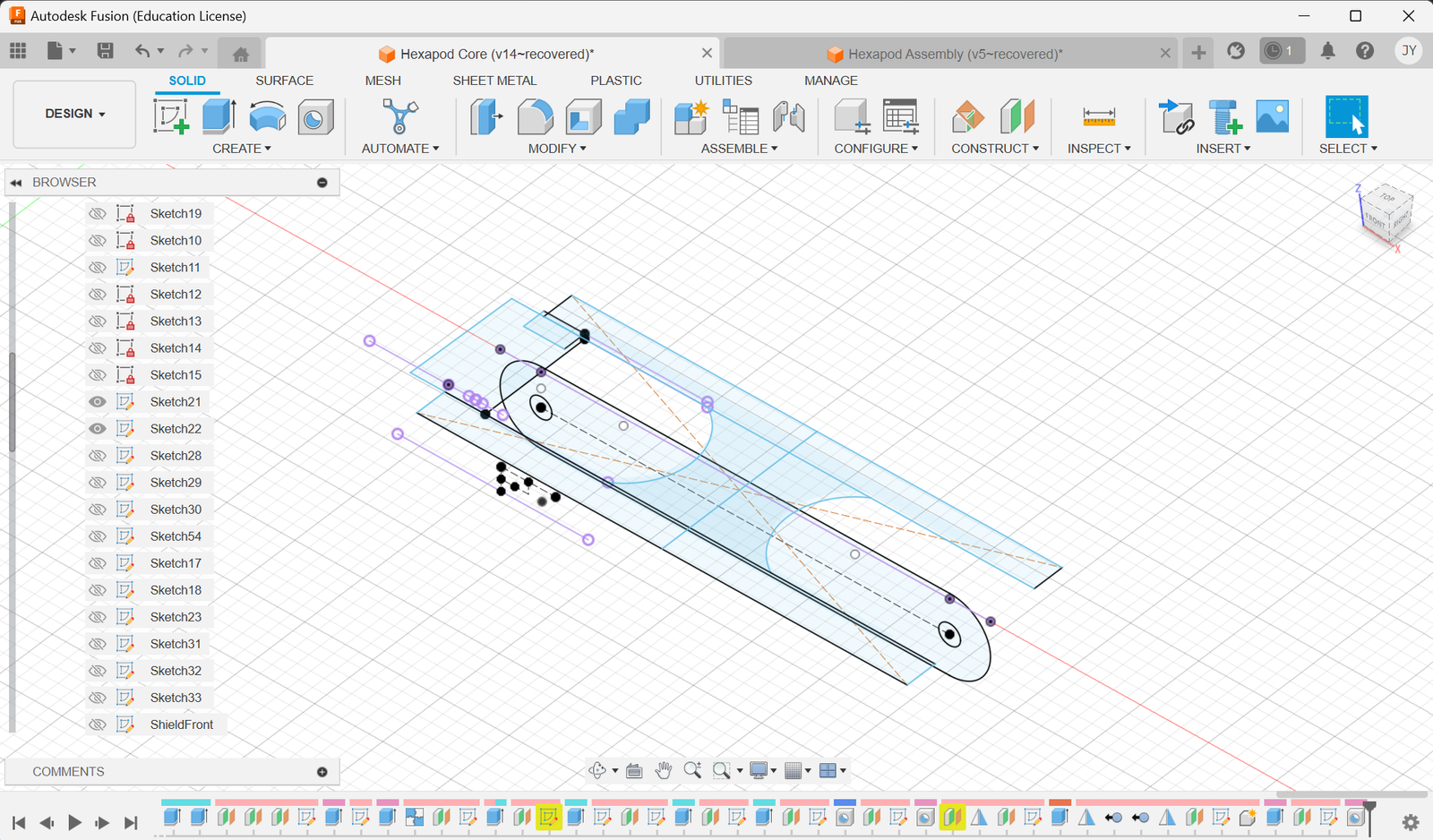

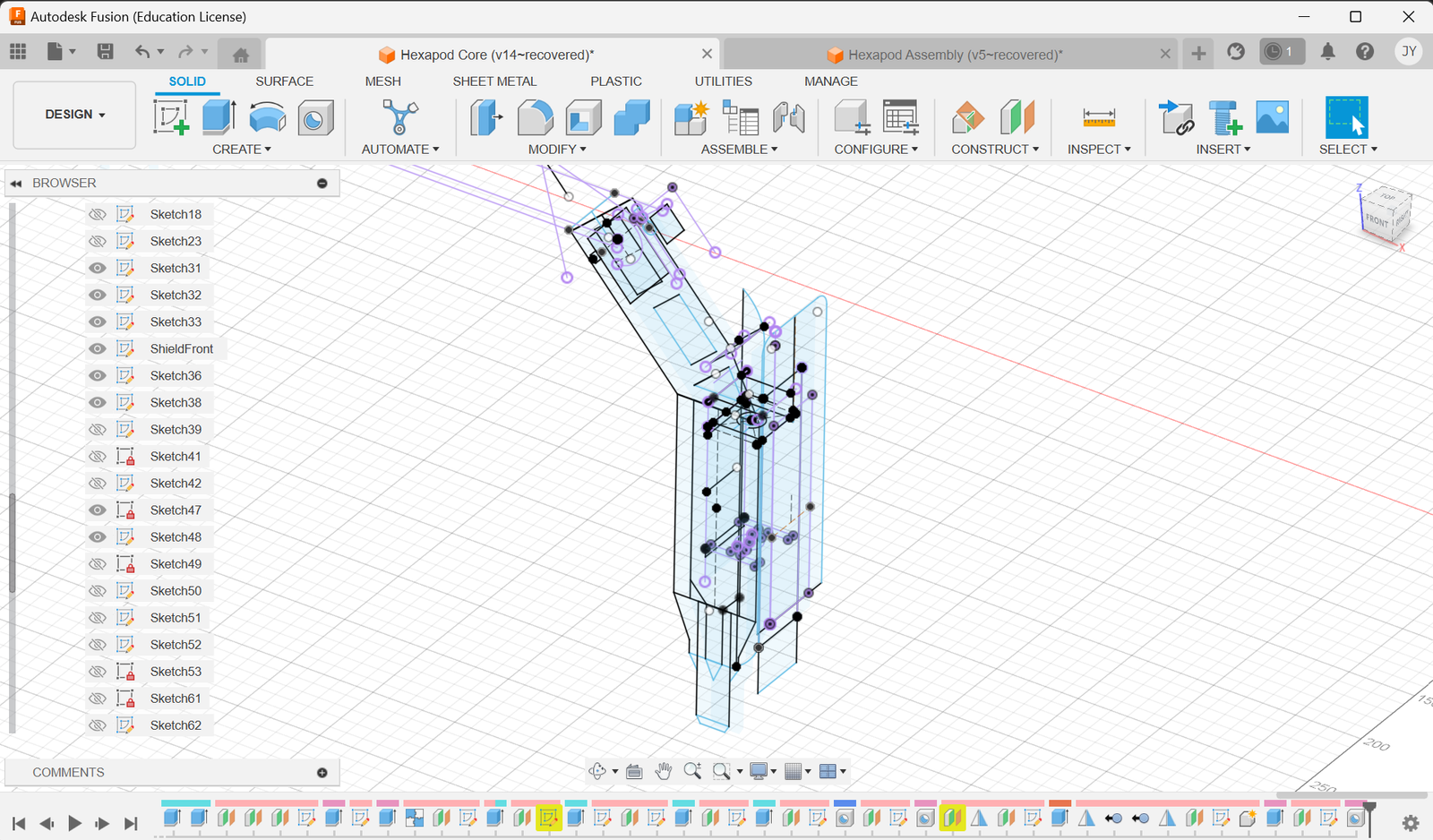

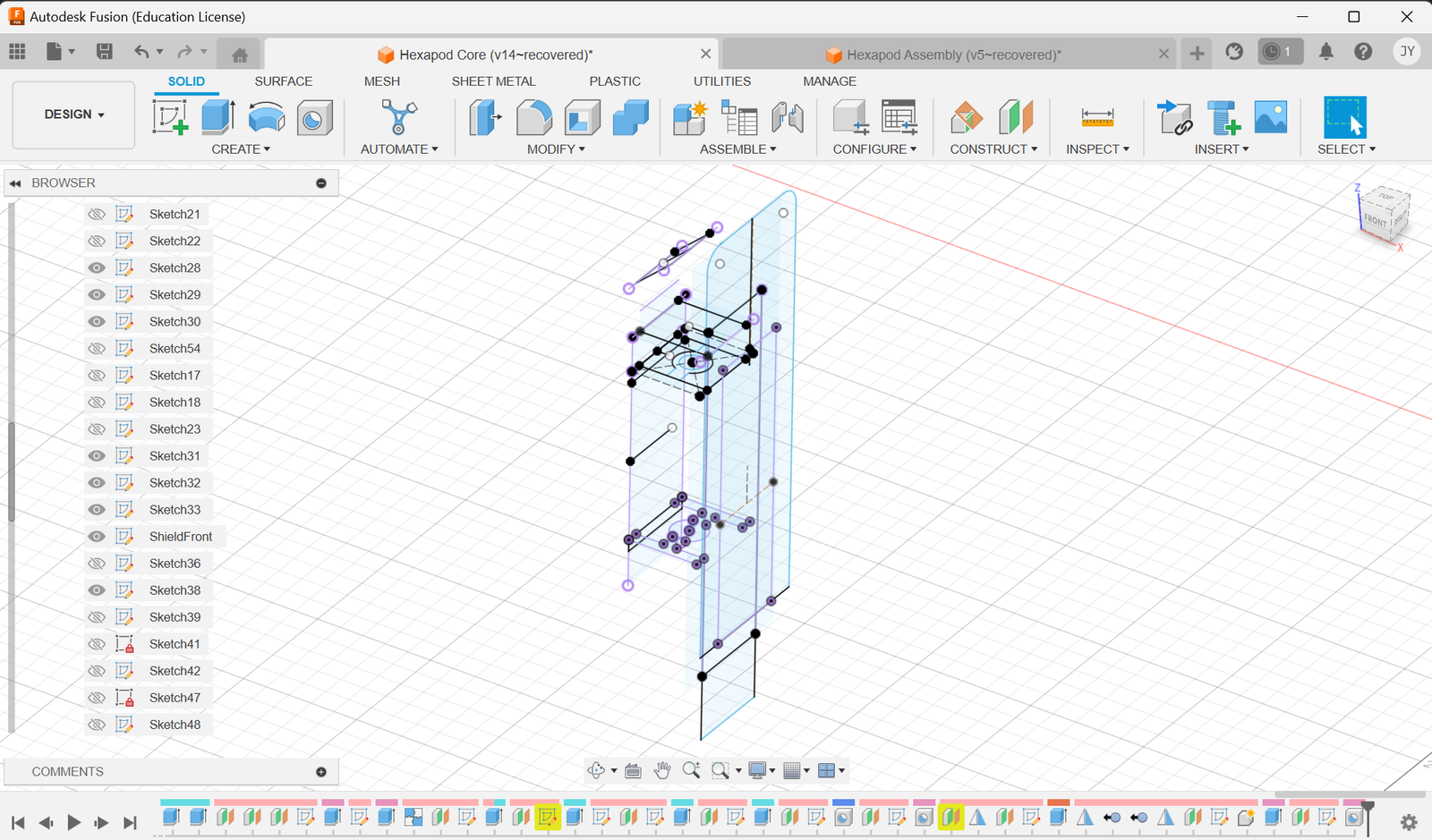

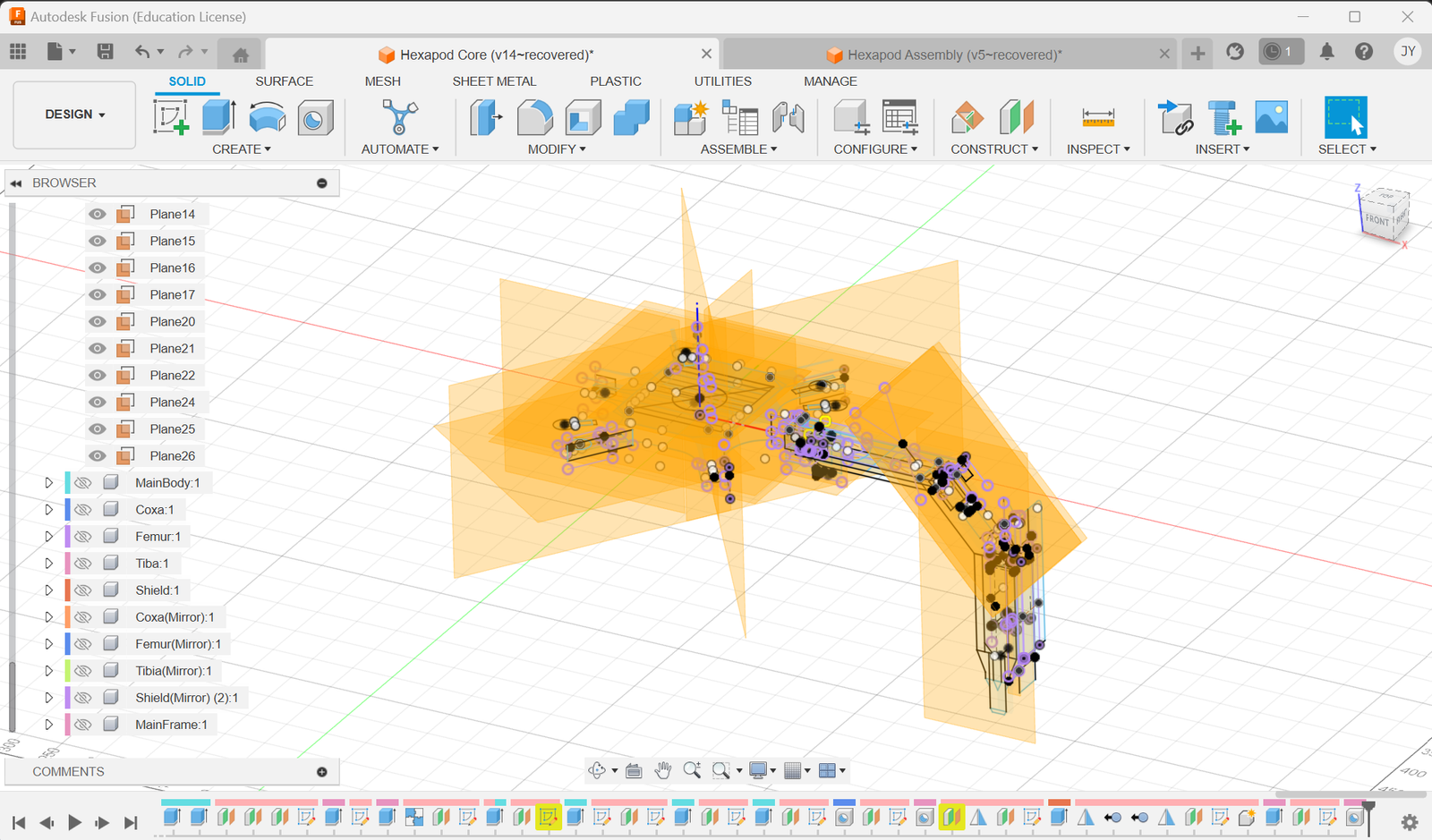

Parameter-driven dimensions so servo pockets, leg clearances, and wiring channels can update without rebuilding the whole assembly.

Design priorities

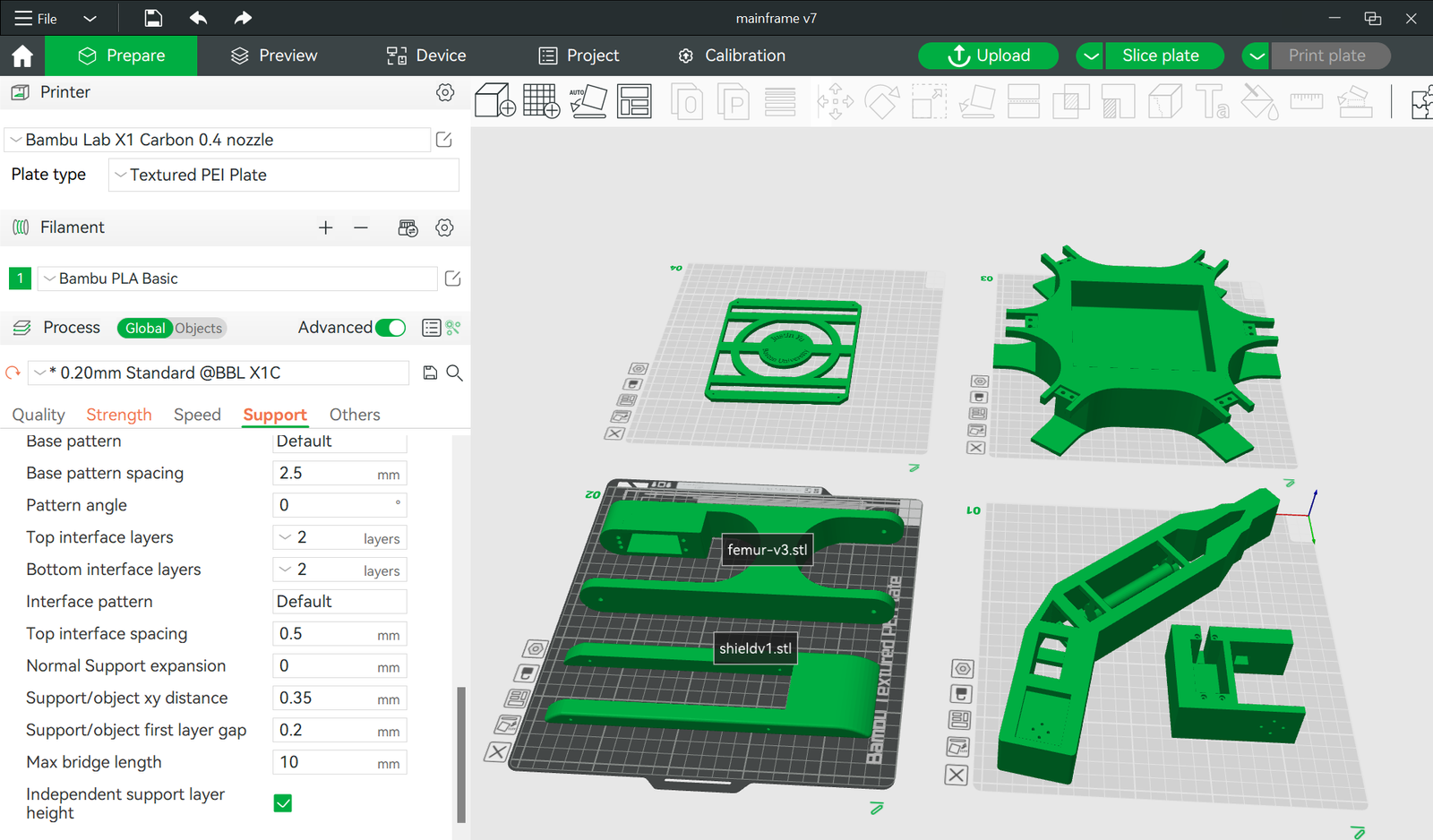

Fit/tolerance, stiffness vs weight, wiring serviceability, and fast revision cycles.

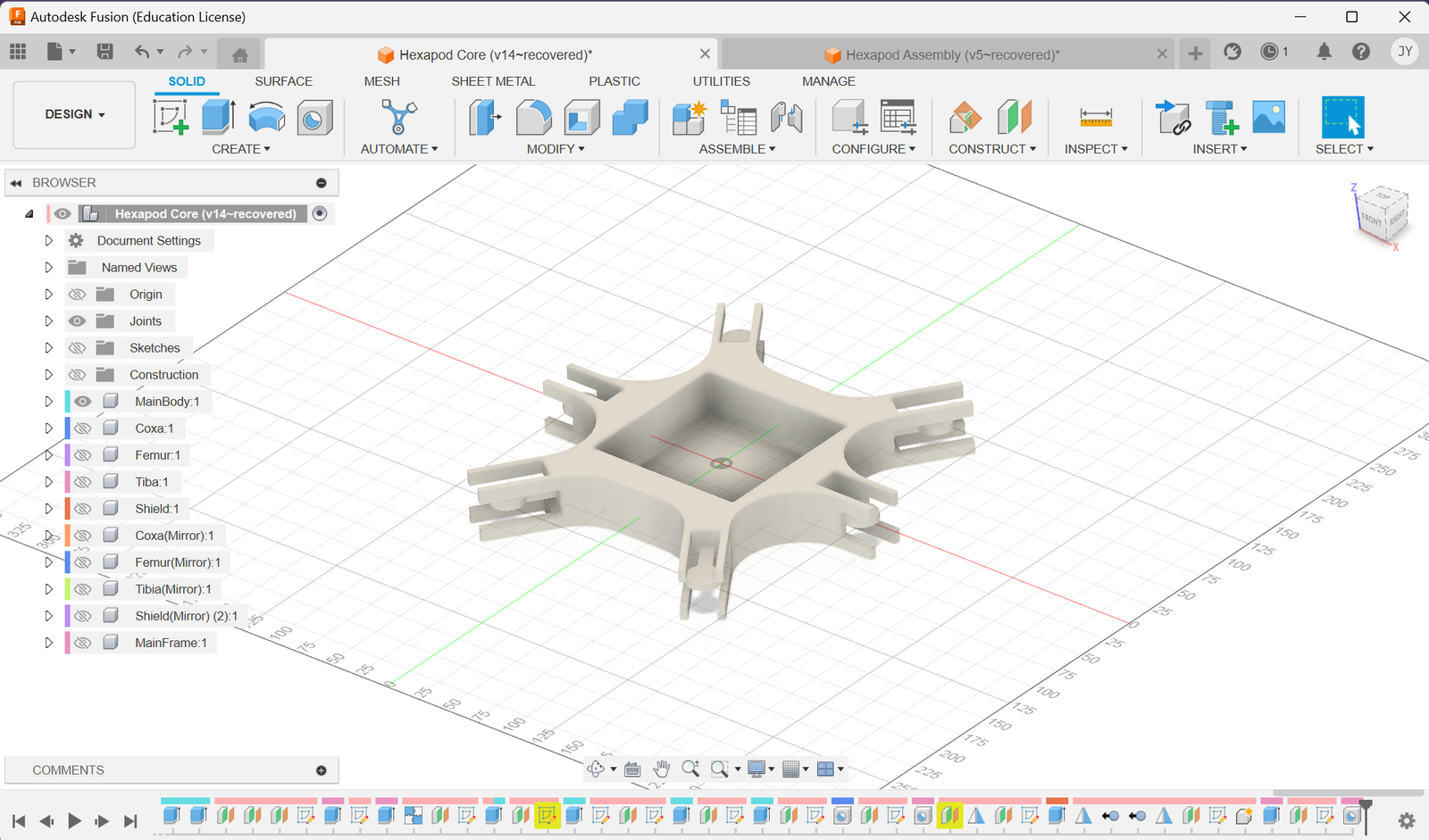

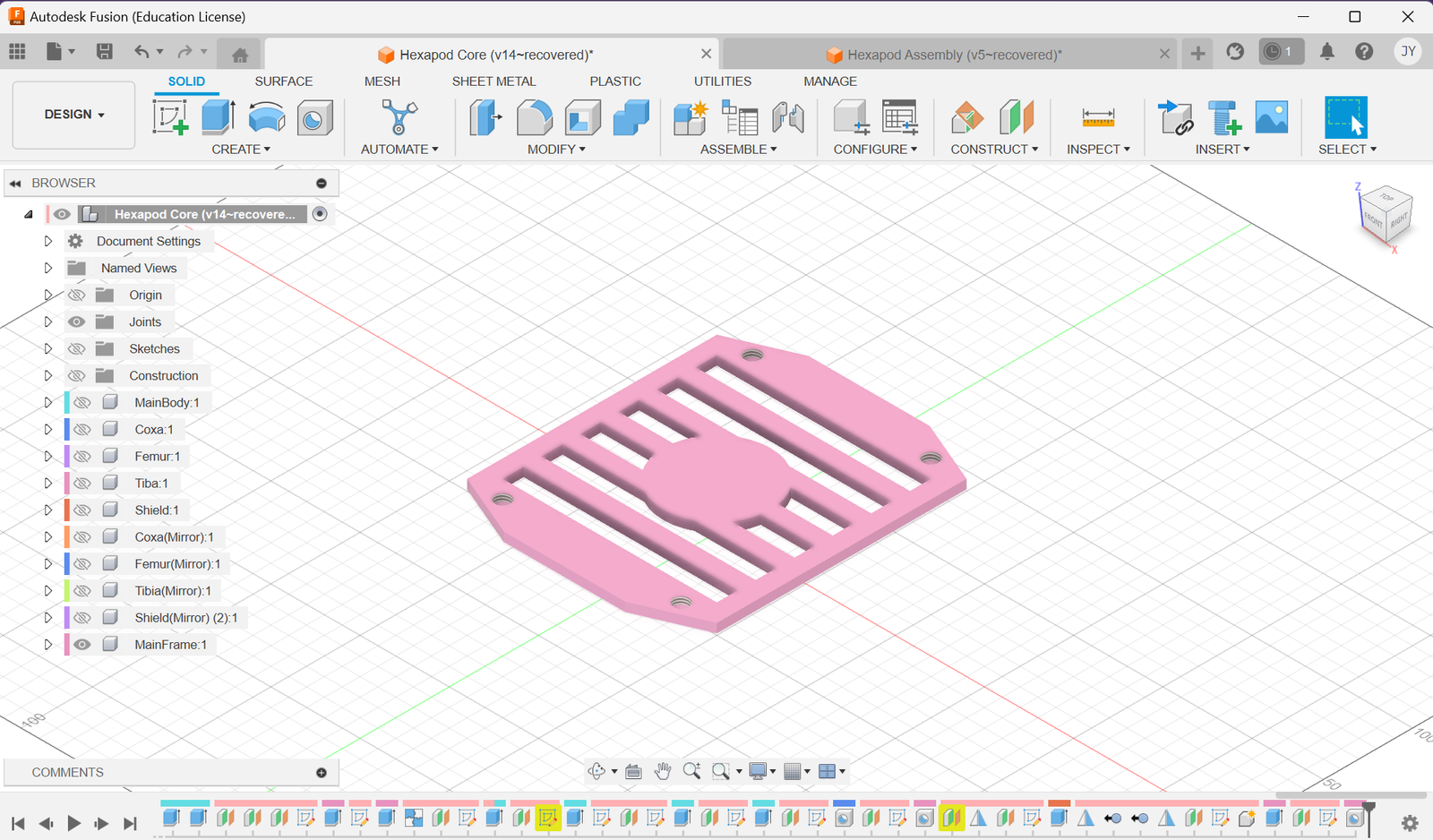

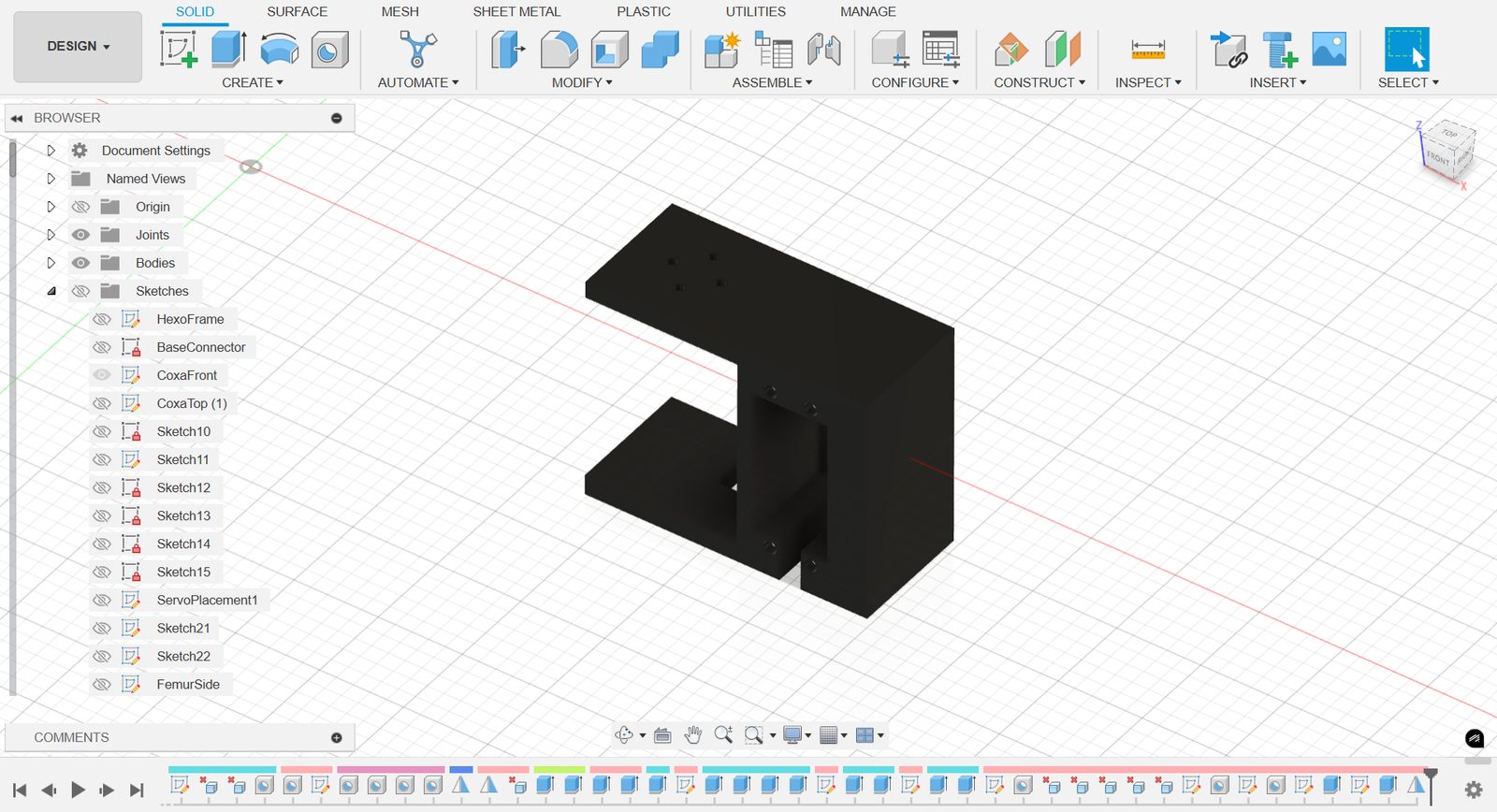

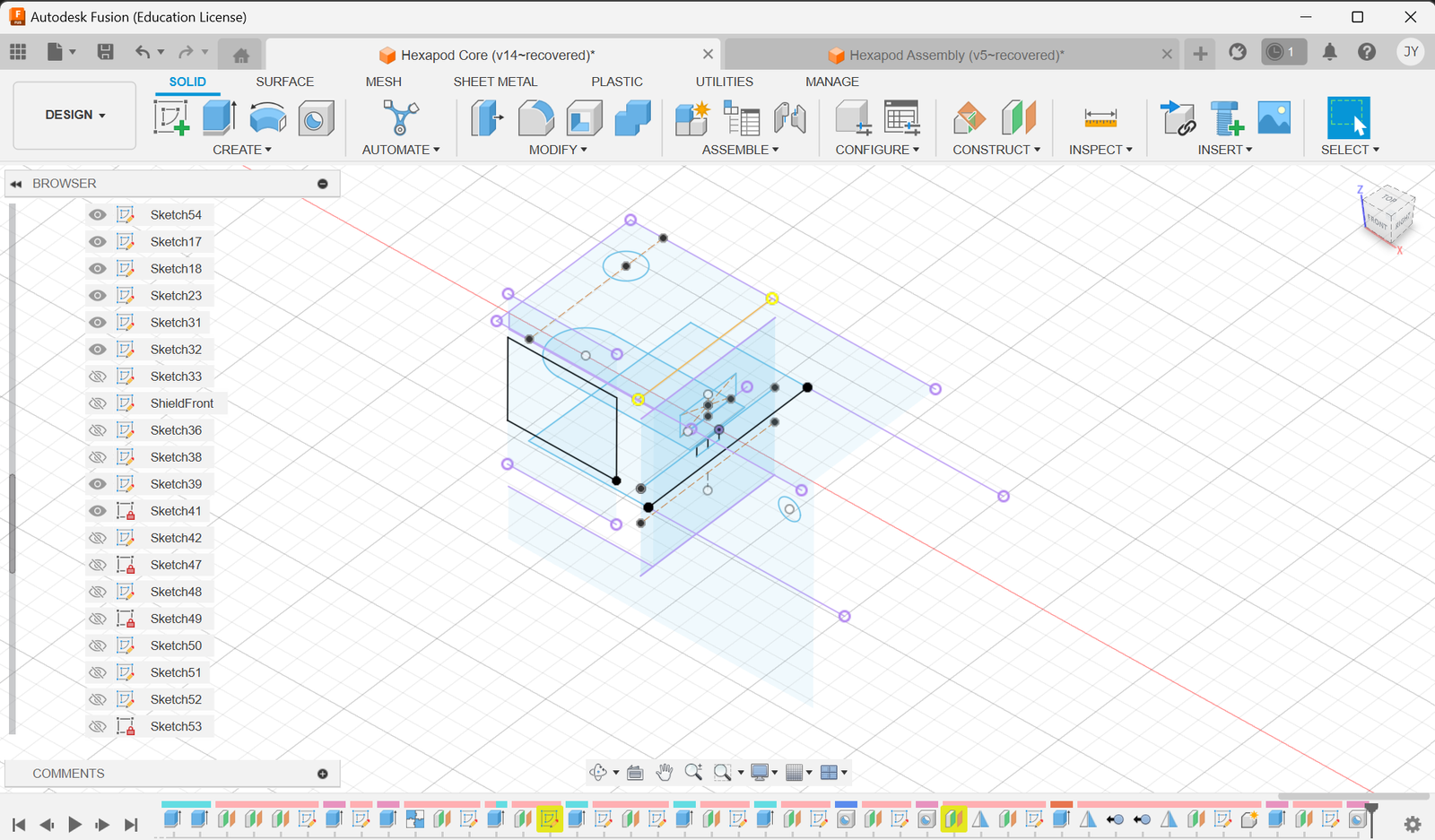

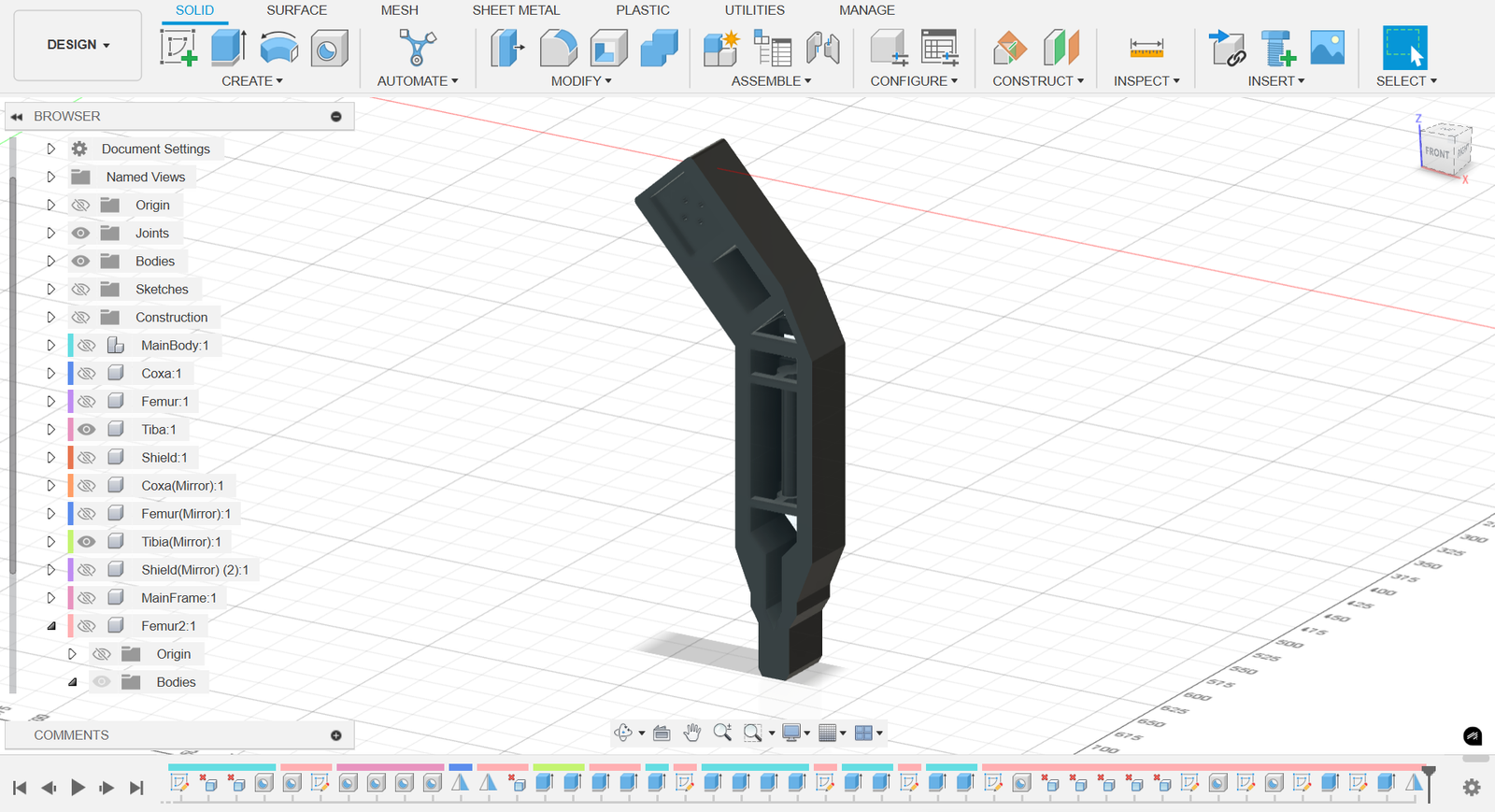

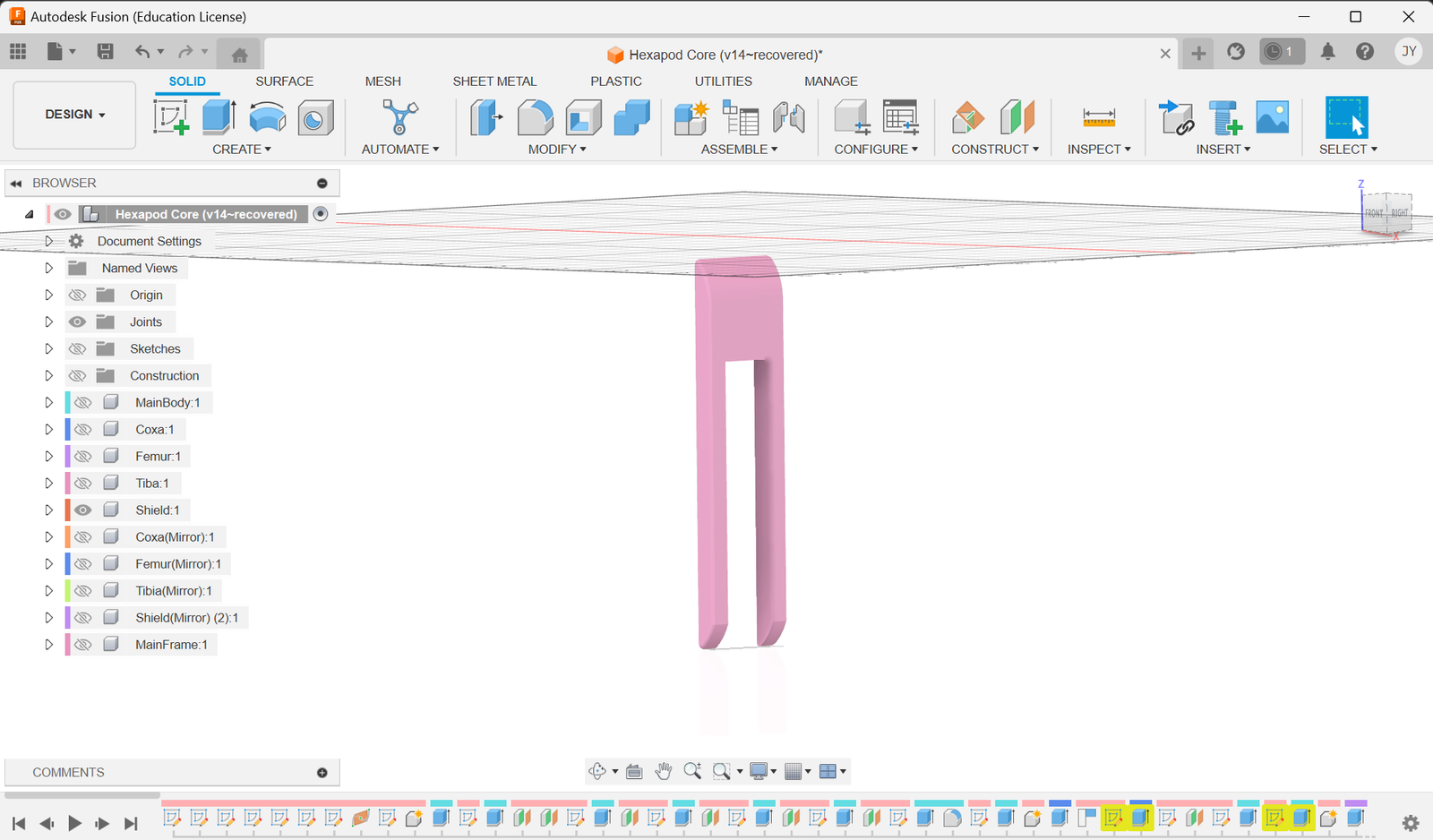

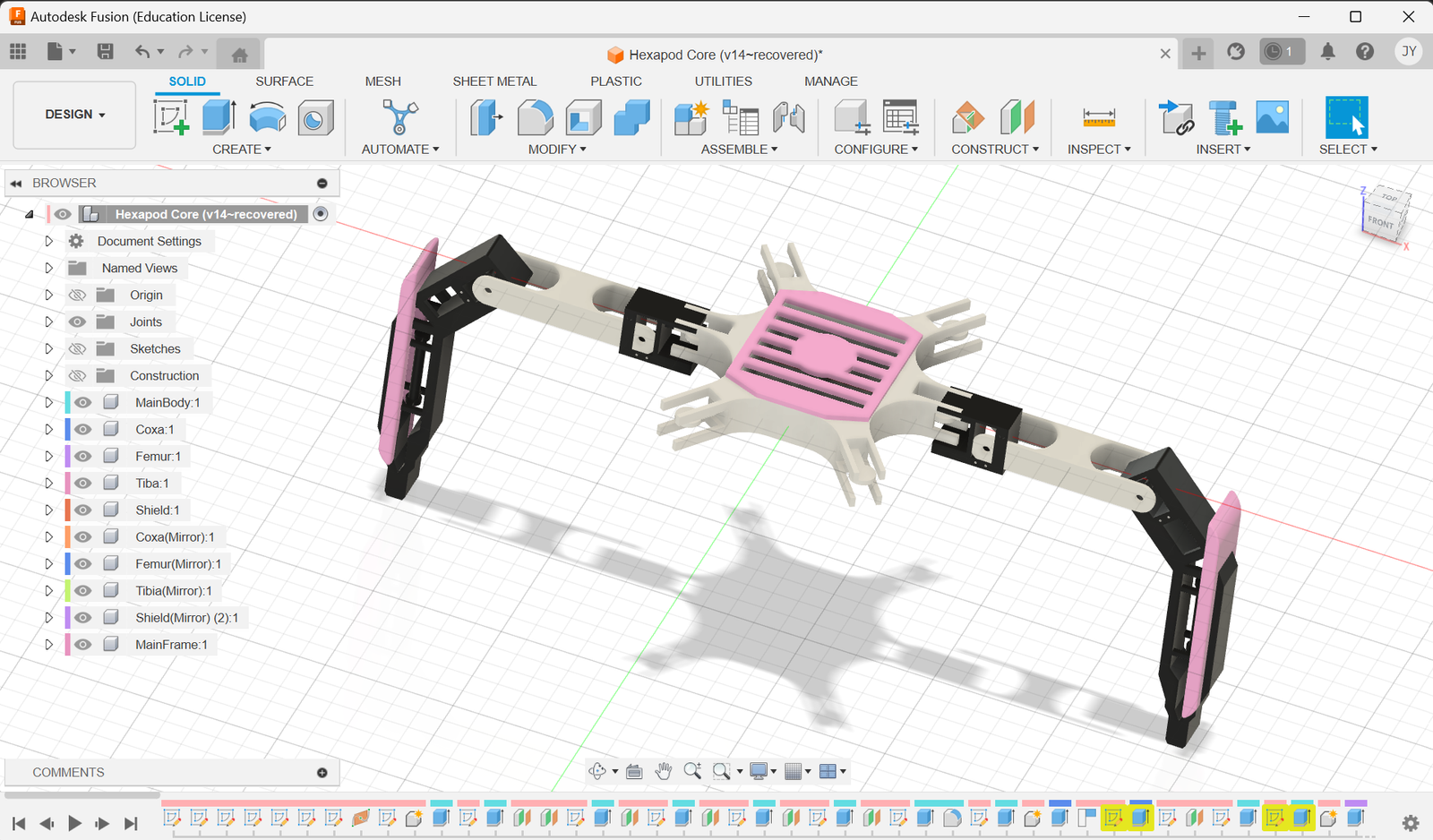

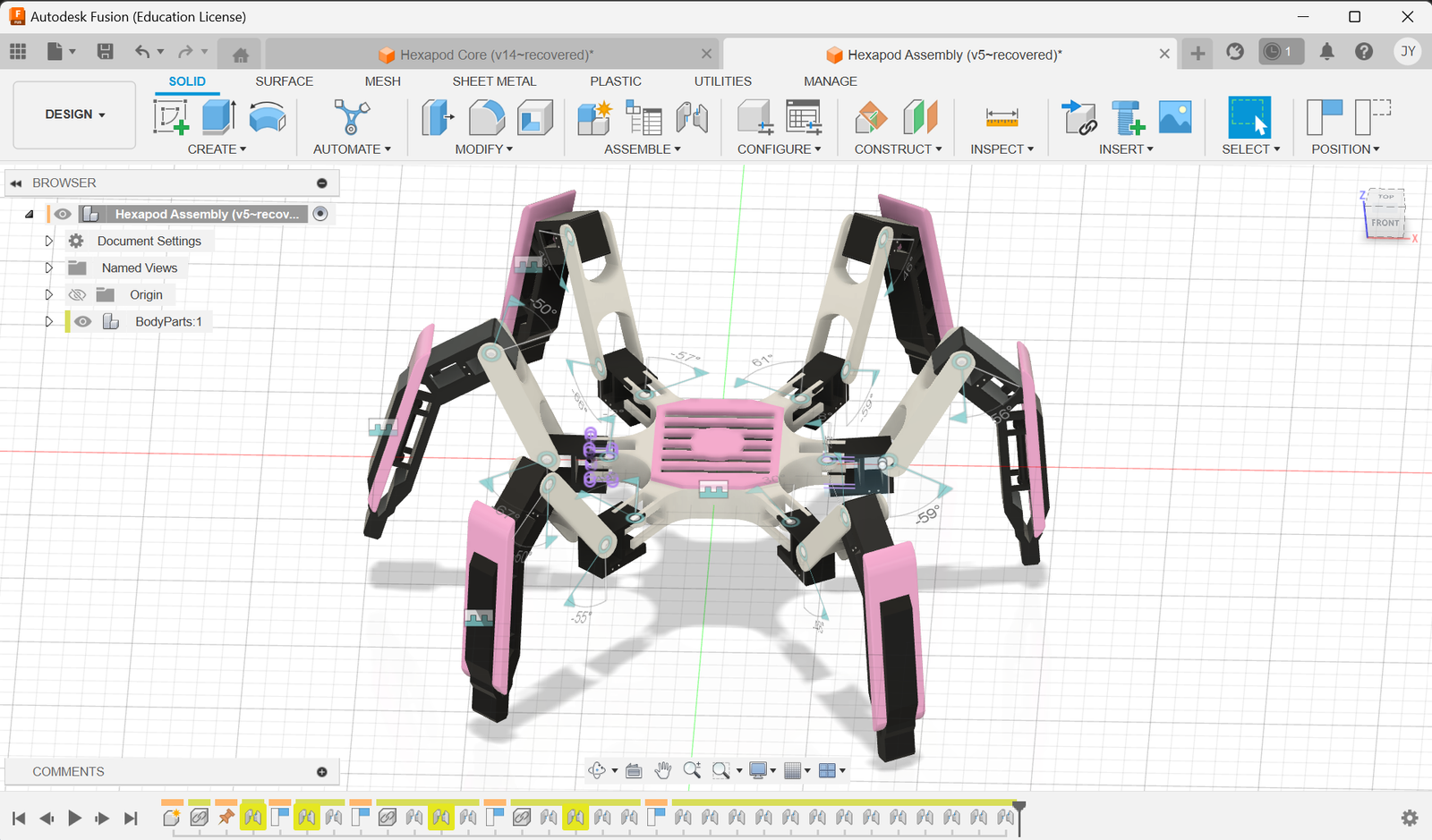

CAD

CAD focused on practical constraints first: servo alignment, fastener access, cable routing, and avoiding interference during gait motion.

Parts & Assembly

The build includes servos, motor drivers, DC-DC regulation, a Raspberry Pi, wiring harnesses, and structural printed parts.

Manufacturing

Print tuning + post-processing for repeatable tolerances and consistent fastener fit.

Integration

Power distribution planning, routing for maintenance, and avoiding cable pinch points.

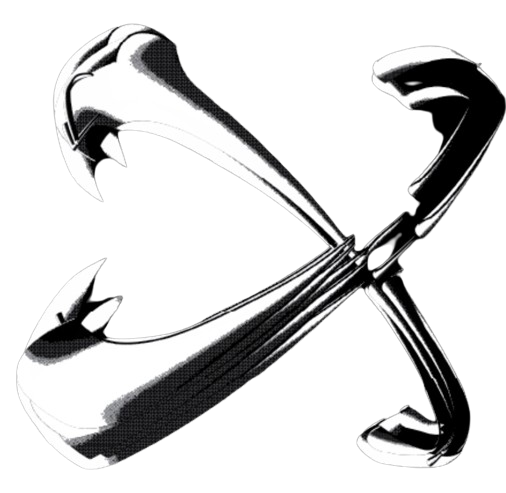

Gallery

3D printed parts and assembly photos.

Results

Major Concerns

FEA — lack of predictive modeling on load stability and insufficient traction.

Most promising direction

Iterative Development increase joint rigidity or material reinforcement (elastomeric overmolding).

Reflection

Challenges

• Balancing torque vs structure stiffness and weight

• Wiring management for maintenance without teardown

• Repeatable prints (tolerances + fastener fits)

What I learned

• Assembly-first CAD thinking

• Iterate: measure → adjust → reprint → validate

• Mechanical + electrical constraints tradeoffs

by Justin Yu

by Justin Yu