Overview

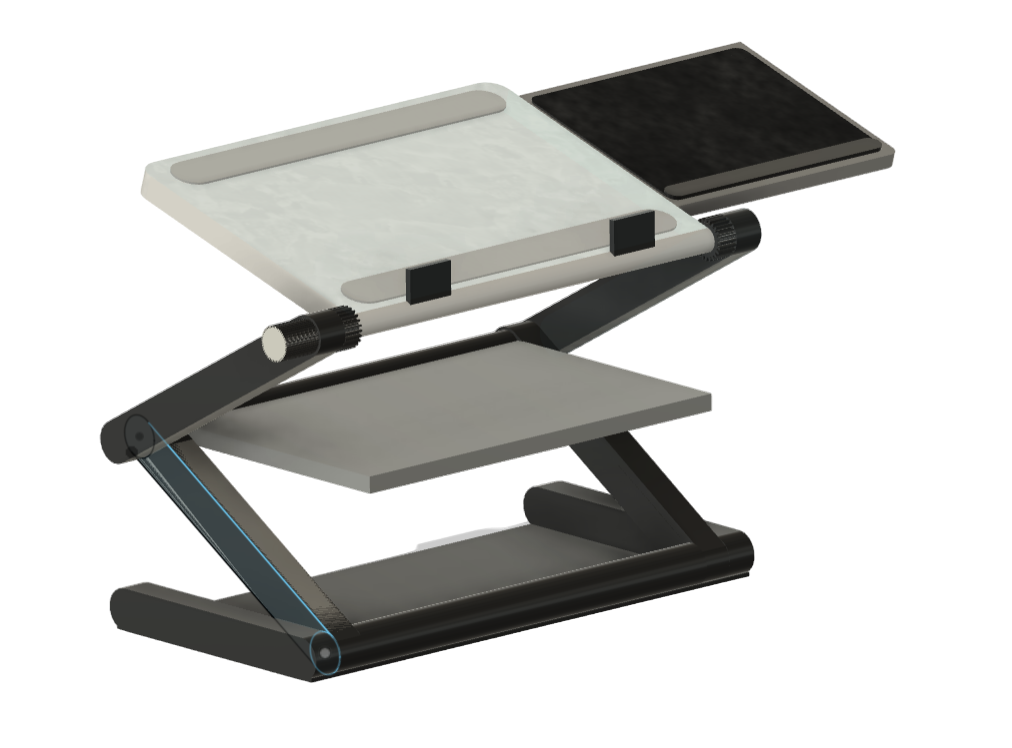

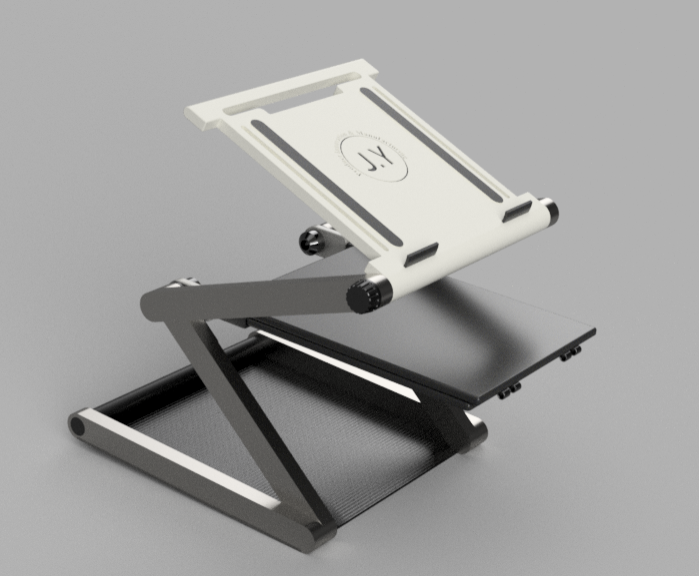

This project explores mechanical design for ergonomics: building a stand that supports multiple working positions while staying stable, compact, and easy to adjust. I modeled the full assembly in Fusion, iterating on hinge concepts and locking methods to balance usability with realistic manufacturability.

Goal

Improve posture and comfort by enabling adjustable height + angle across different environments (desk, bed, couch).

Design priorities

Stability, repeatable locking positions, minimal part complexity, and straightforward assembly.

Design Process

The stand went through multiple concept passes. Early iterations focused on the frame geometry, then evolved into a more deliberate approach: identify what must adjust (angle + writing surface), then design the hinge/lock system around those requirements. I intentionally removed features that added complexity without reliability (like a retractable internal mousepad tray).

Key decision

Keep the adjustment mechanism simple and robust instead of “feature-heavy”. Reliability beats novelty in anything that needs daily use.

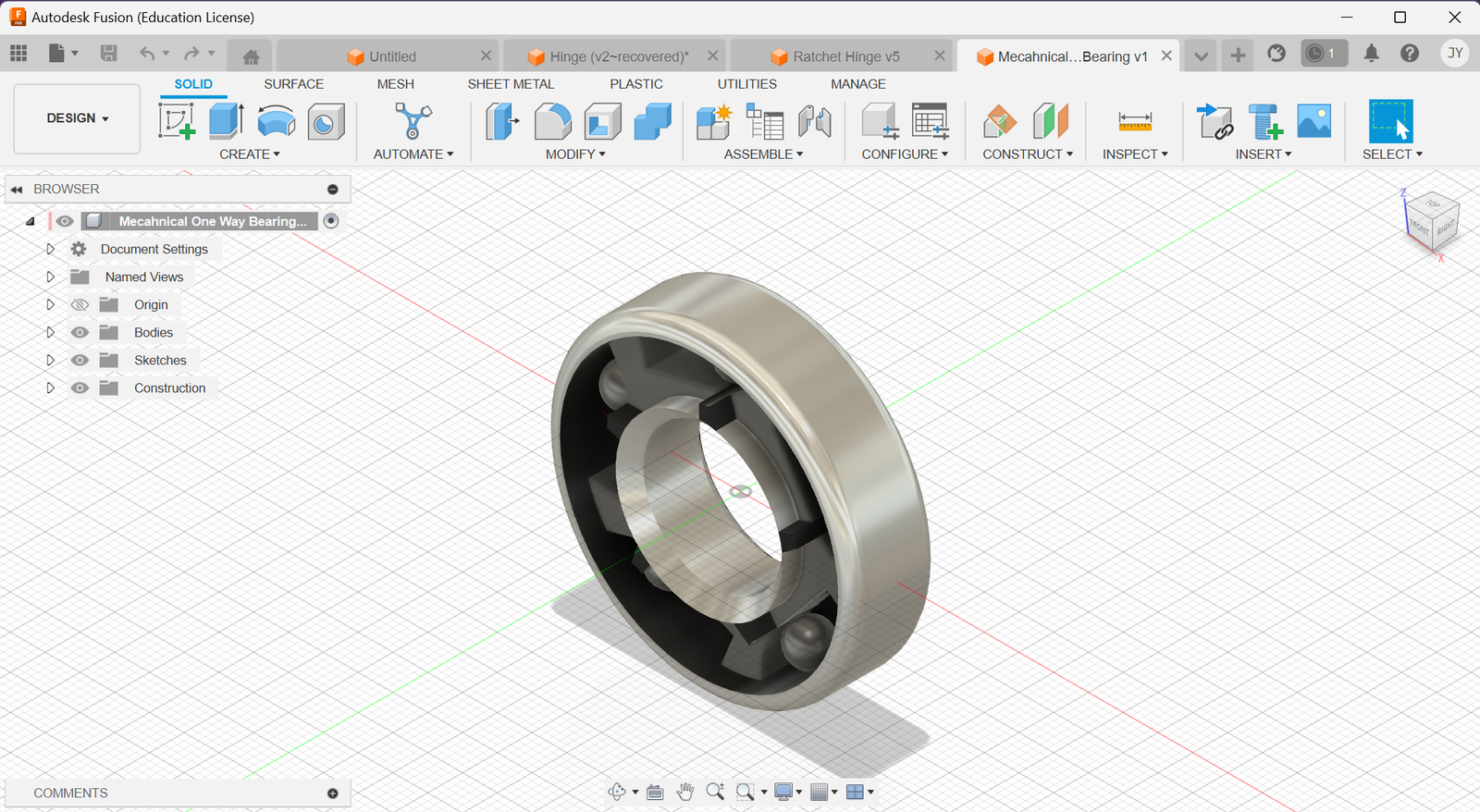

CAD skills used

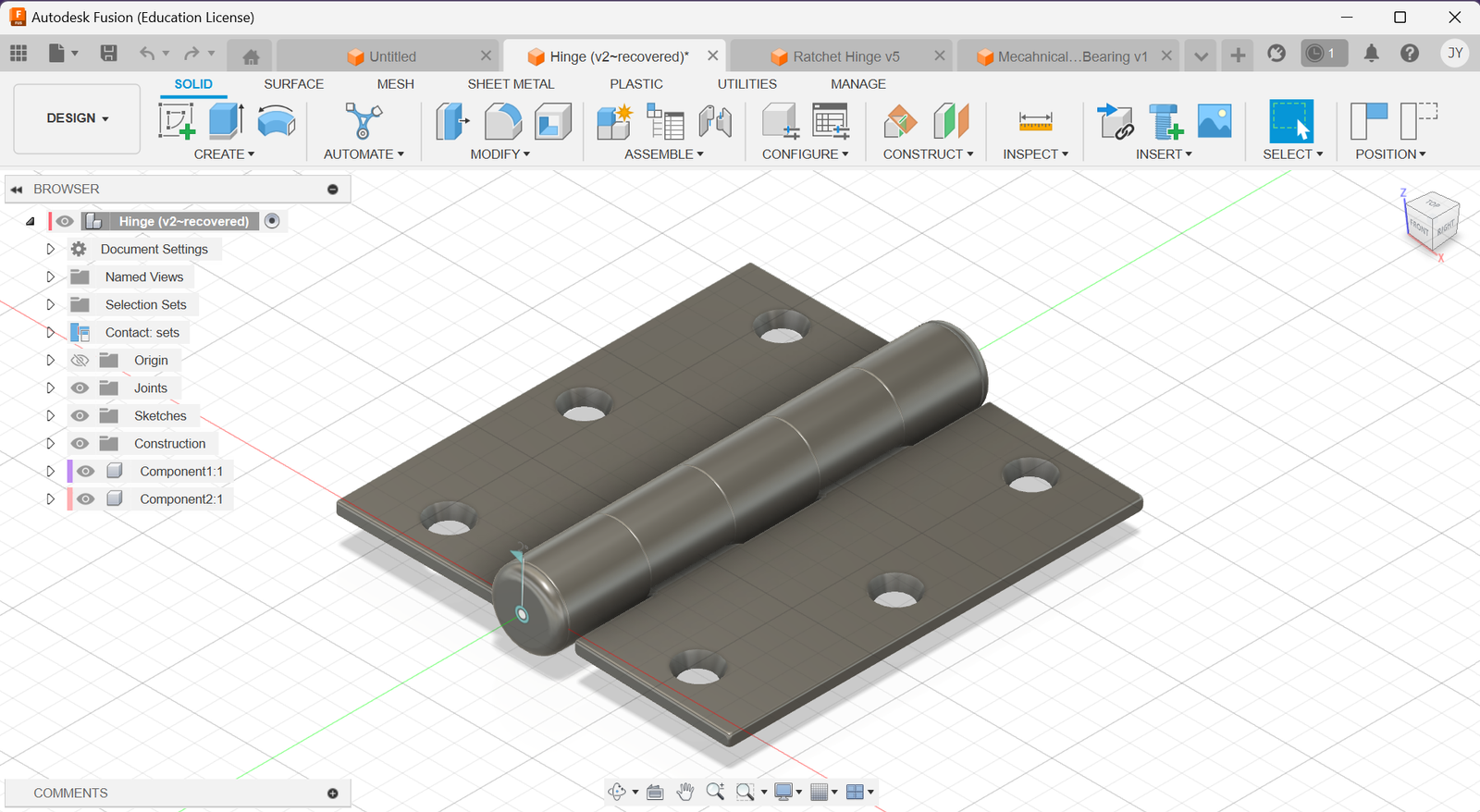

Joint motion + sets, projections, press-pull, parametric edits, interference checking, and mechanism-driven iteration.

Mechanical Components

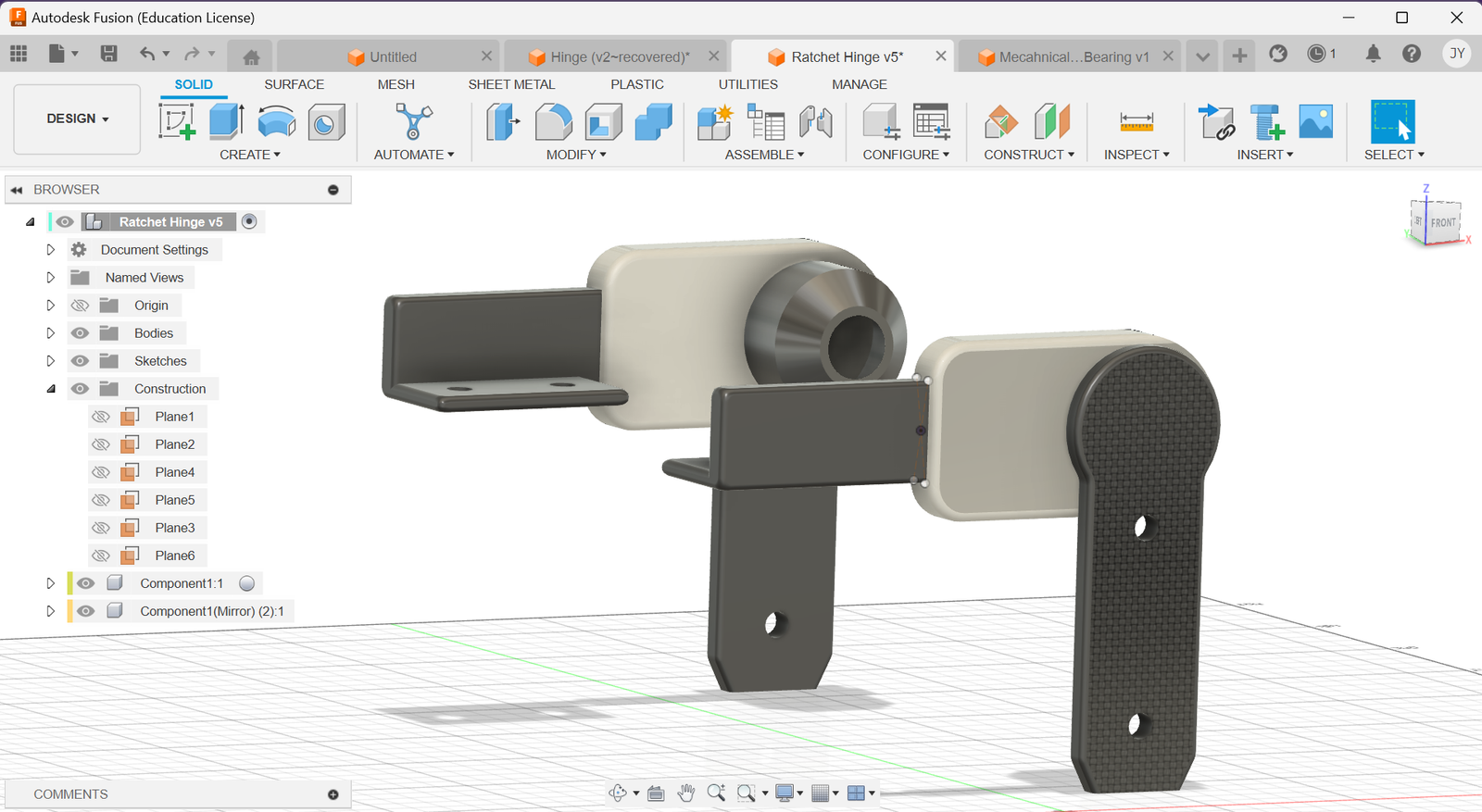

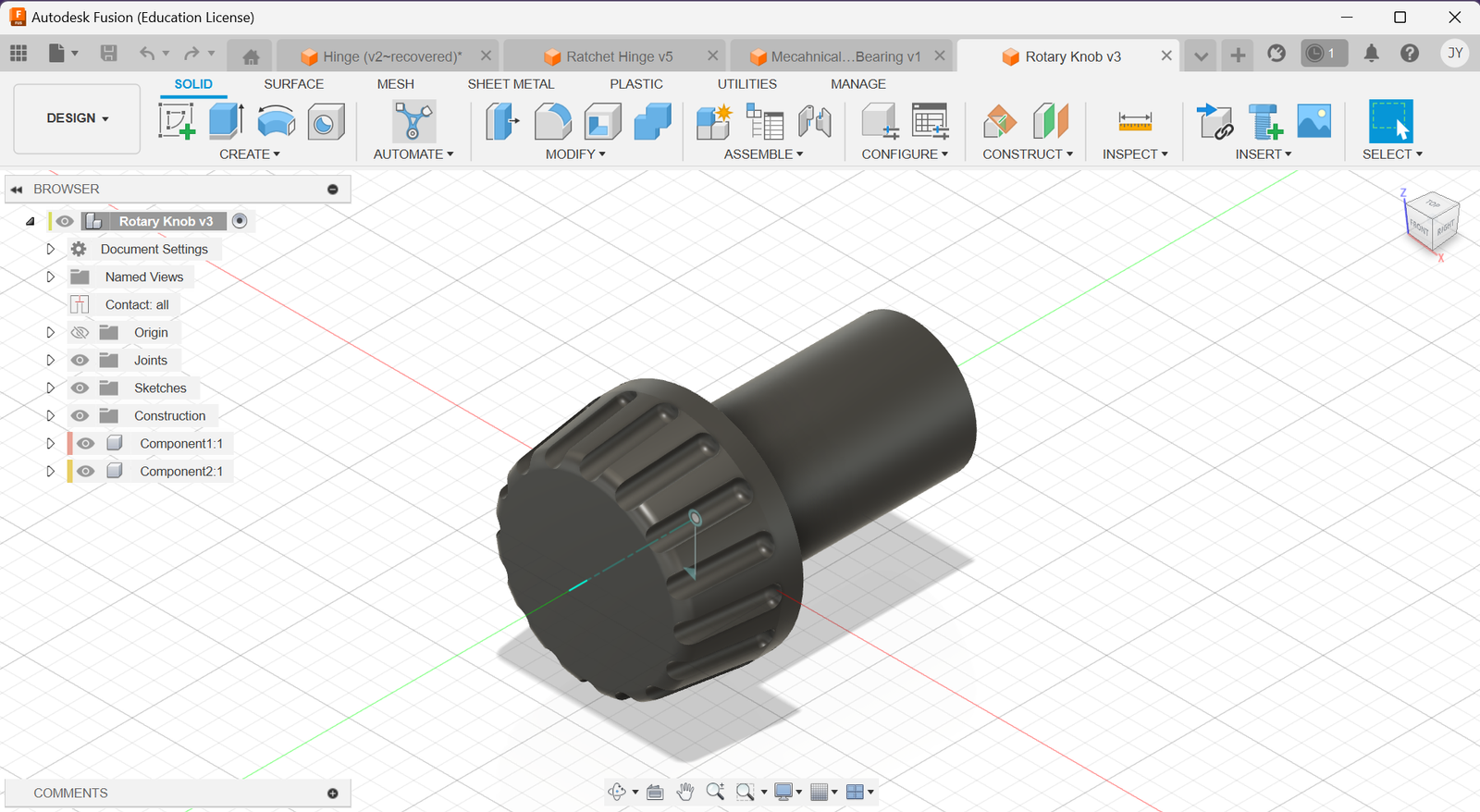

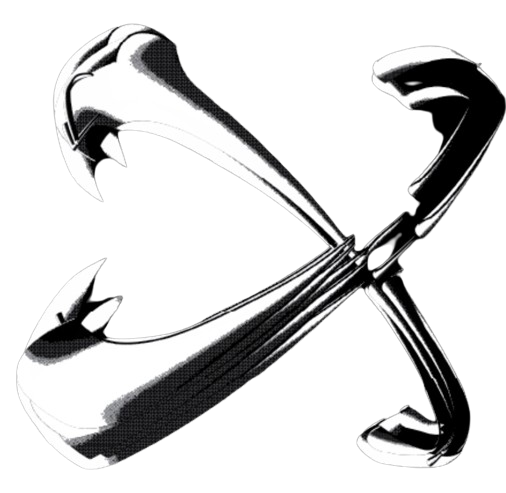

The core of the design is the adjustment system: the stand must move smoothly, then lock securely at useful angles. I focused on two mechanisms: a ratcheting hinge for the writing surface flap, and a rotary/locking knob concept for incline adjustment. Multiple axle approaches were explored (including bearing concepts), then narrowed to the simplest solution that still met stability needs.

Ratcheting hinge

Designed for repeatable angle stops and solid “set-and-stay” behavior, with emphasis on manufacturable geometry for future prototype testing.

Knob + lock approach

Focused on comfortable adjustment and positive locking under load, while avoiding finicky mechanisms that would loosen over time.

Manufacturing

This project was designed with prototyping in mind: parts that can be 3D printed for form/fit testing, and components that could transition to basic metal fabrication for improved rigidity. The assembly strategy stays modular so I can swap mechanisms without redesigning the entire frame.

Prototype plan

Print the frame + hinge prototypes for iteration; validate angle ranges, stability, and clearances with a real laptop load.

Next manufacturing step

Upgrade key load-bearing members to metal (or reinforced prints) after fit is validated, then redesign for repeatable fastener interfaces.

Results

The final CAD concept achieves the intended adjustment ranges while maintaining a coherent assembly. The biggest gain was learning to treat mechanisms as first-class design constraints; geometry is easy, but reliable locking and repeatable adjustment is the real challenge.

What worked

Iterative simplification: removing risky features (like the retractable tray) made the final design more realistic and buildable.

What I’d improve

Add explicit load testing assumptions (force/torque at hinge), then size hinge teeth/lock friction to match.

Reflection

Challenges

• Converging on a locking mechanism that’s both smooth and secure.

• Designing parts that are realistic to prototype with limited shop/tool access.

• Balancing feature ideas with what actually increases reliability.

What I learned

• Mechanism-first CAD thinking (motion + constraints drive the design).

• Iterate: simplify → validate → refine, instead of stacking features.

• Design-for-prototyping habits (modular parts, testable assumptions).

by Justin Yu

by Justin Yu