Overview

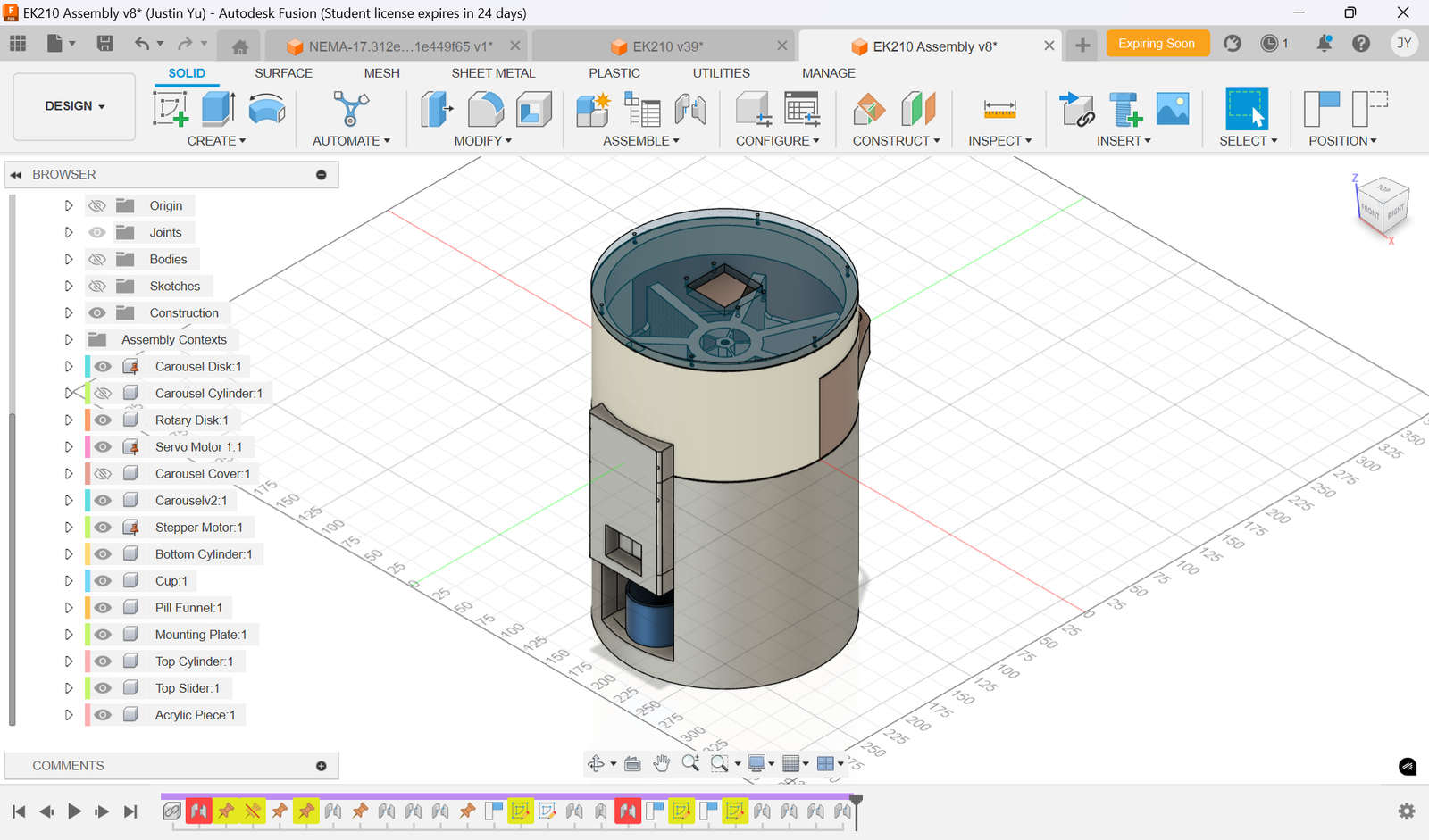

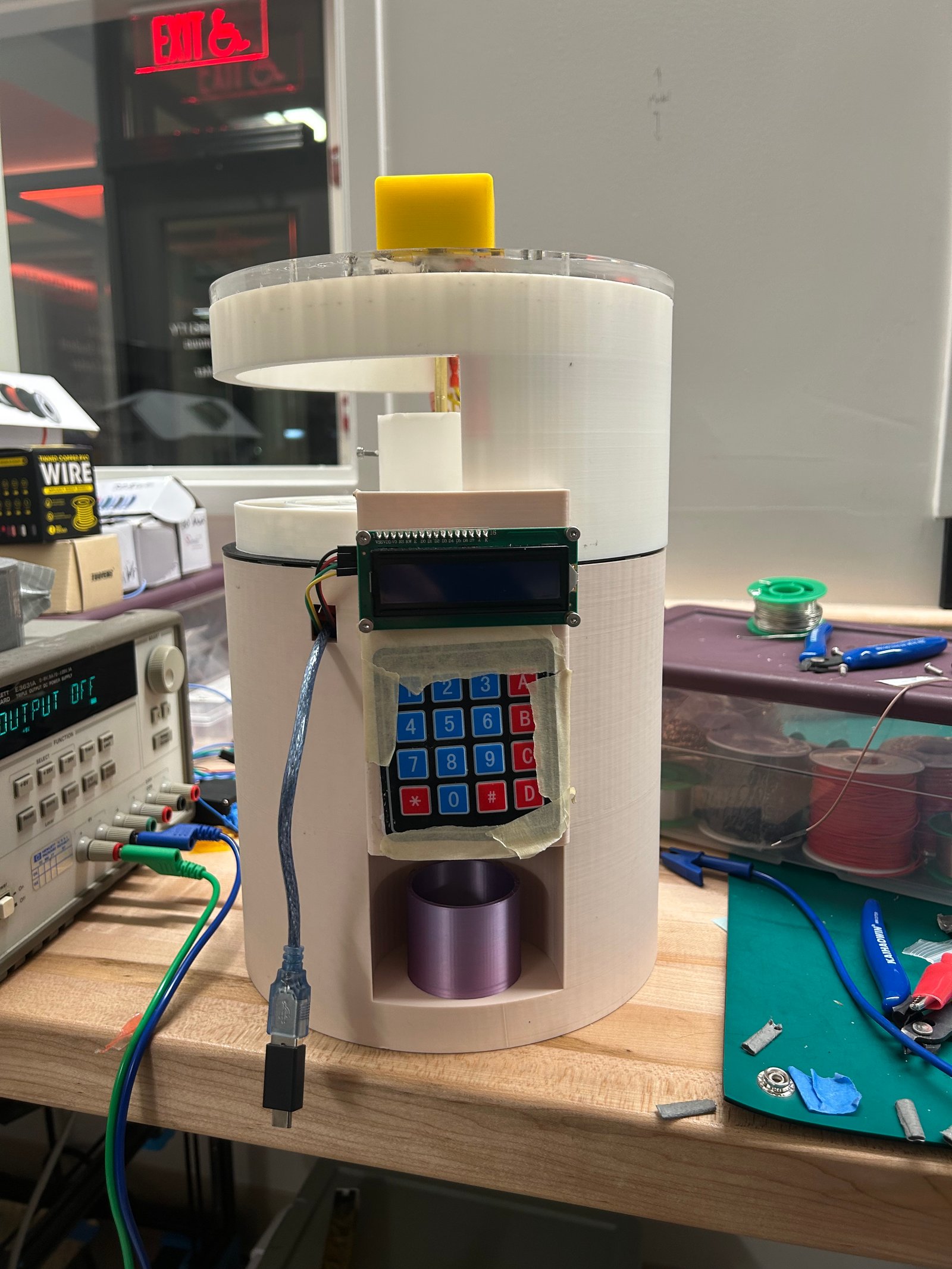

For our Engineering Design course, we designed an automated pill dispenser with the goal of being compact, user-friendly, and dependable for elderly/disabled users. The device provides visual + audio reminders and dispenses pills through a mechanically actuated carousel + funnel mechanism.

Design goals

Reliable dispensing, clear reminders, compact packaging, and easy interaction.

Build methods

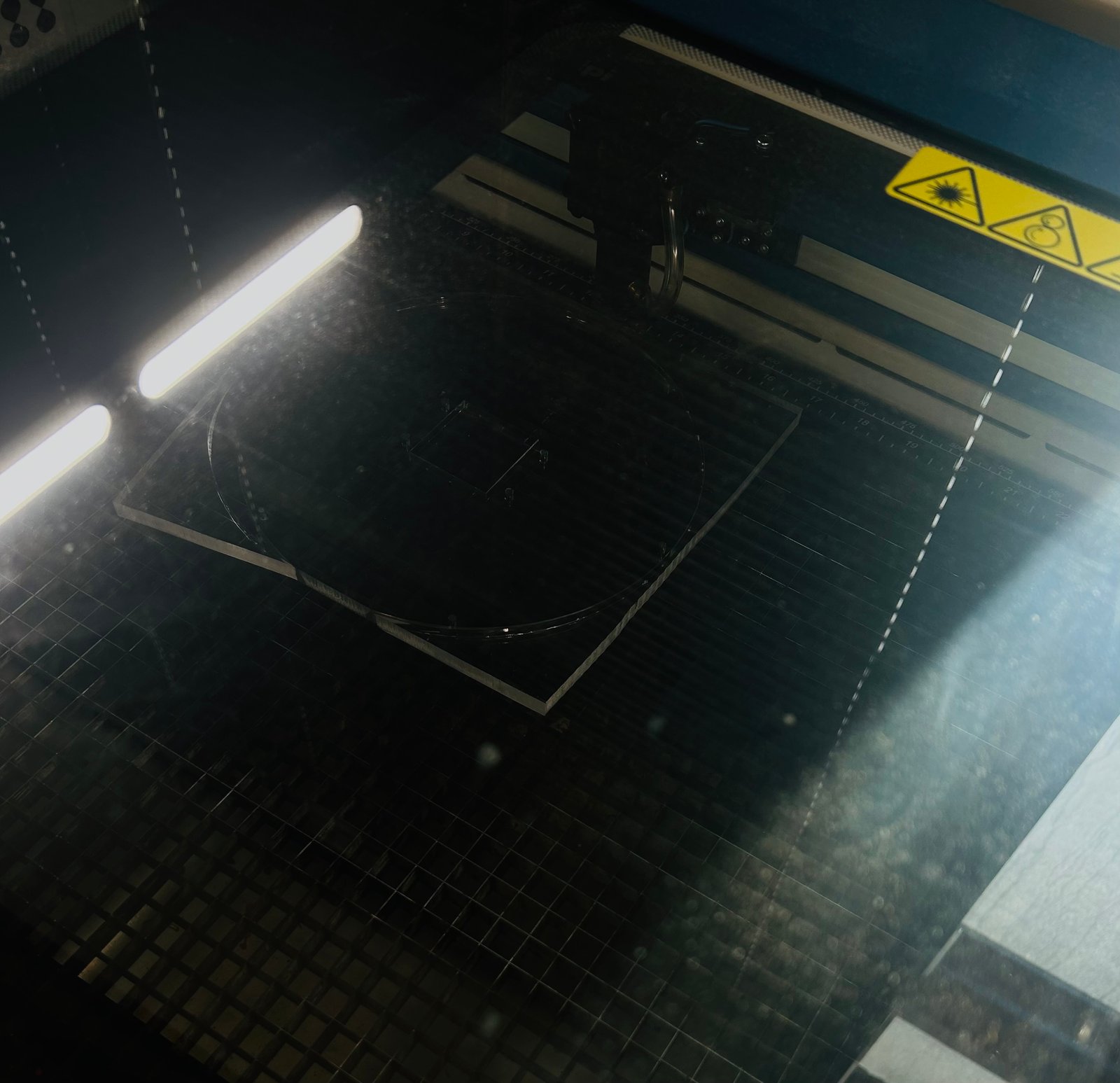

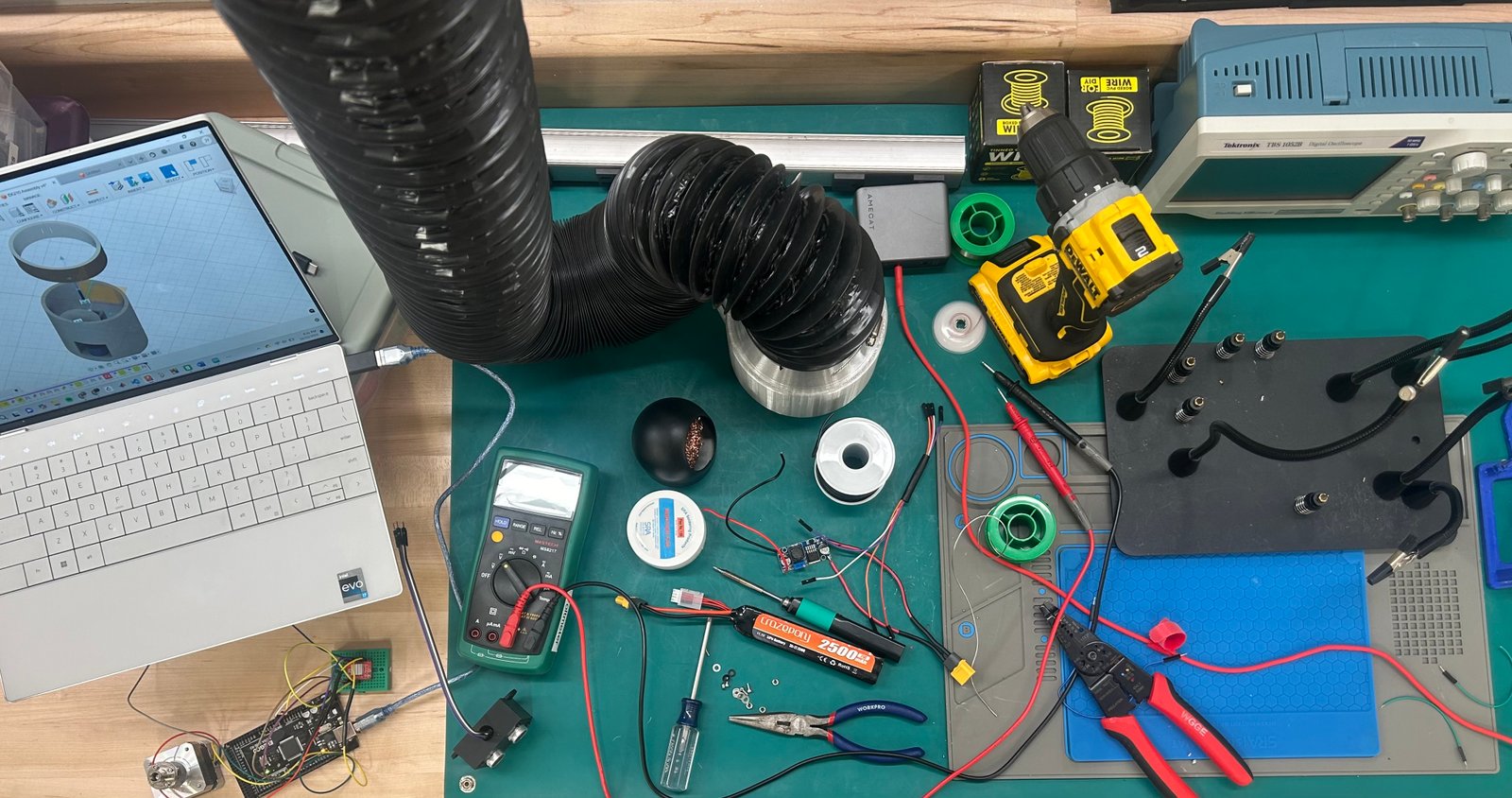

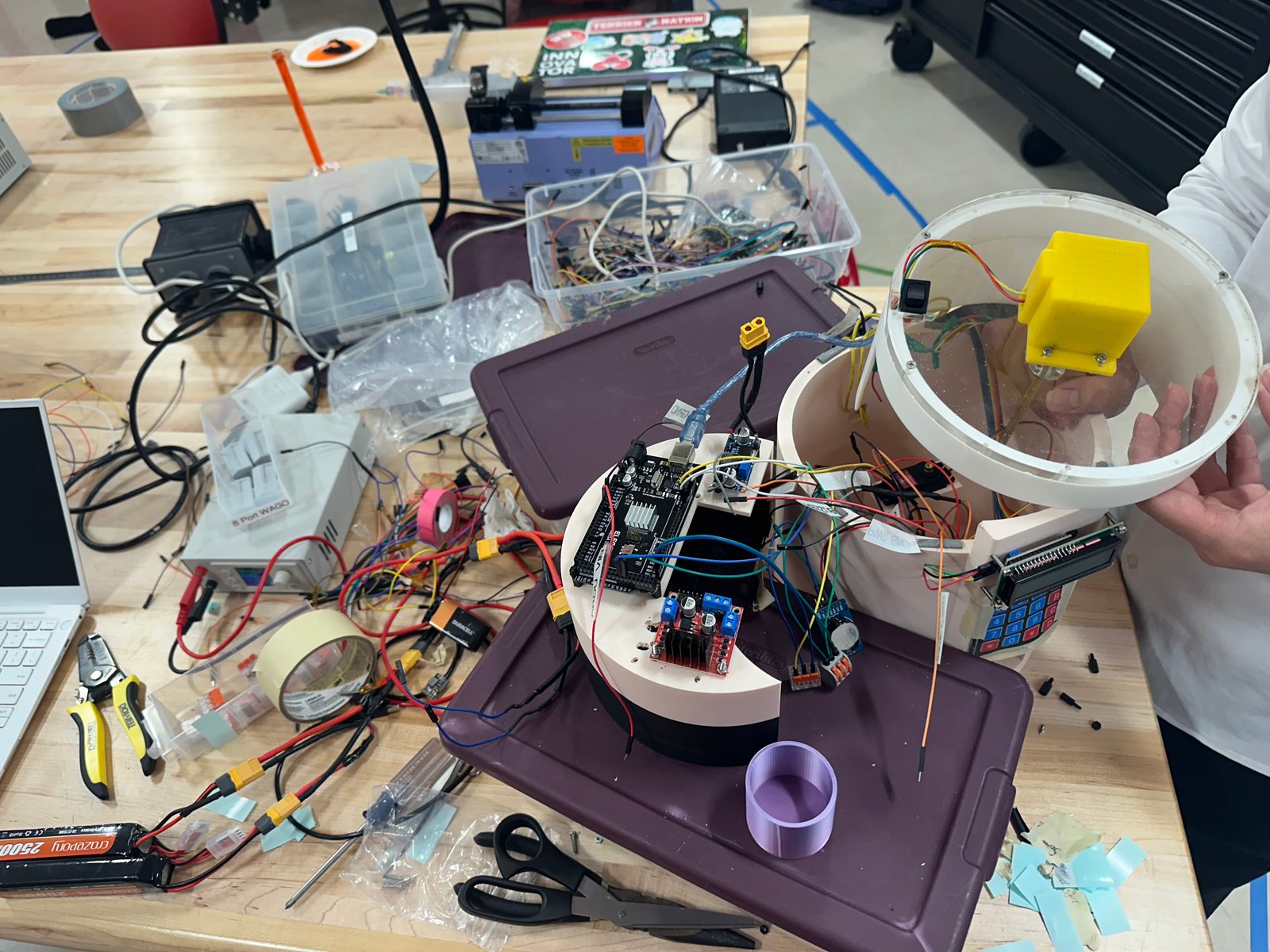

Fusion 360 CAD, 3D printing, laser cutting, manual fabrication, wiring + debugging.

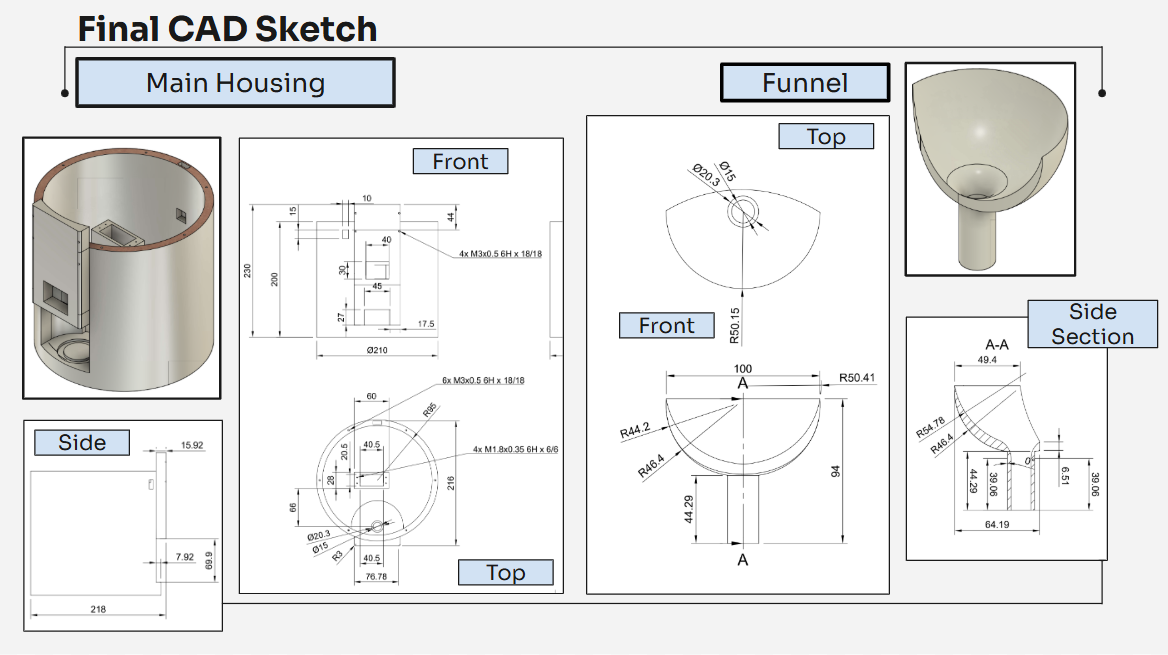

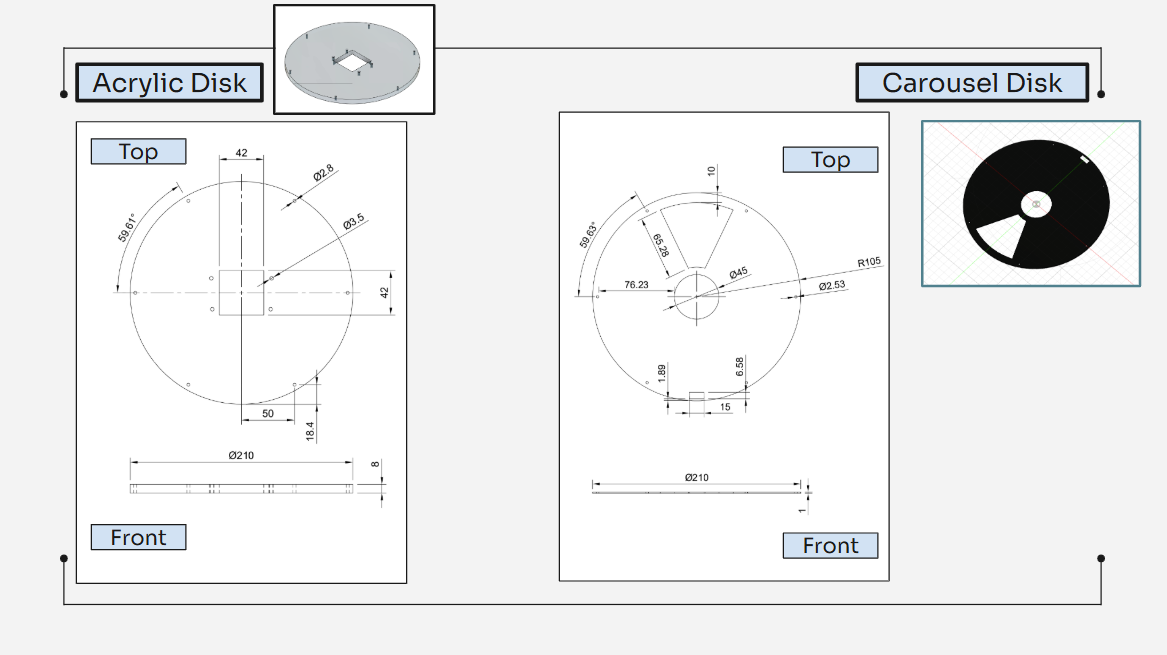

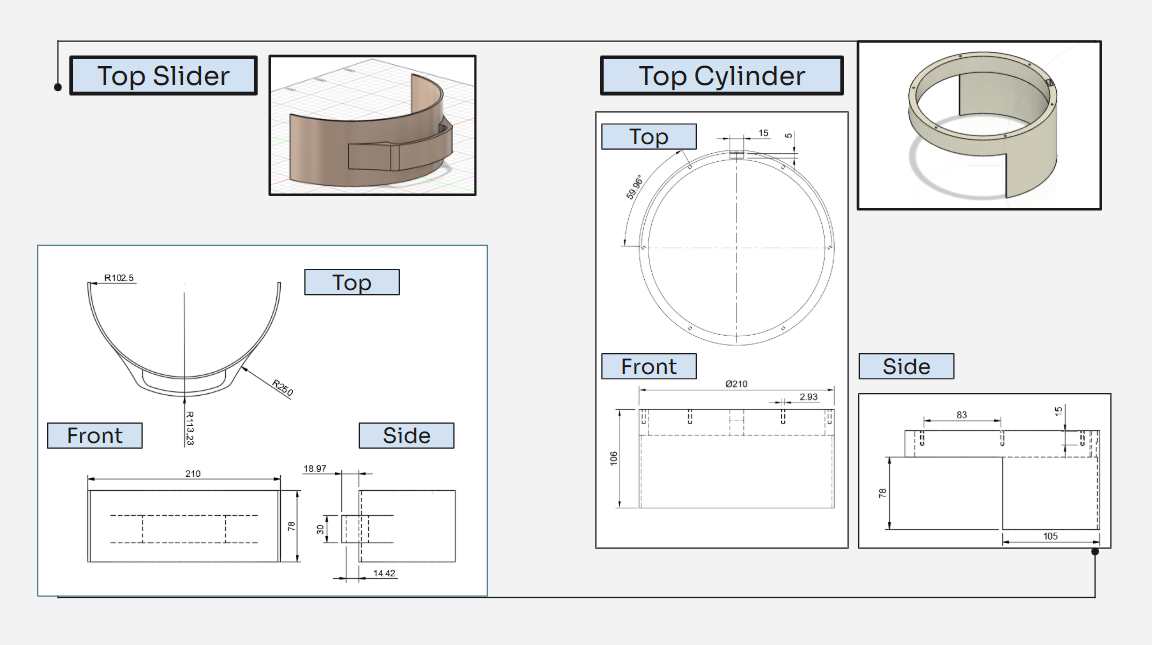

CAD

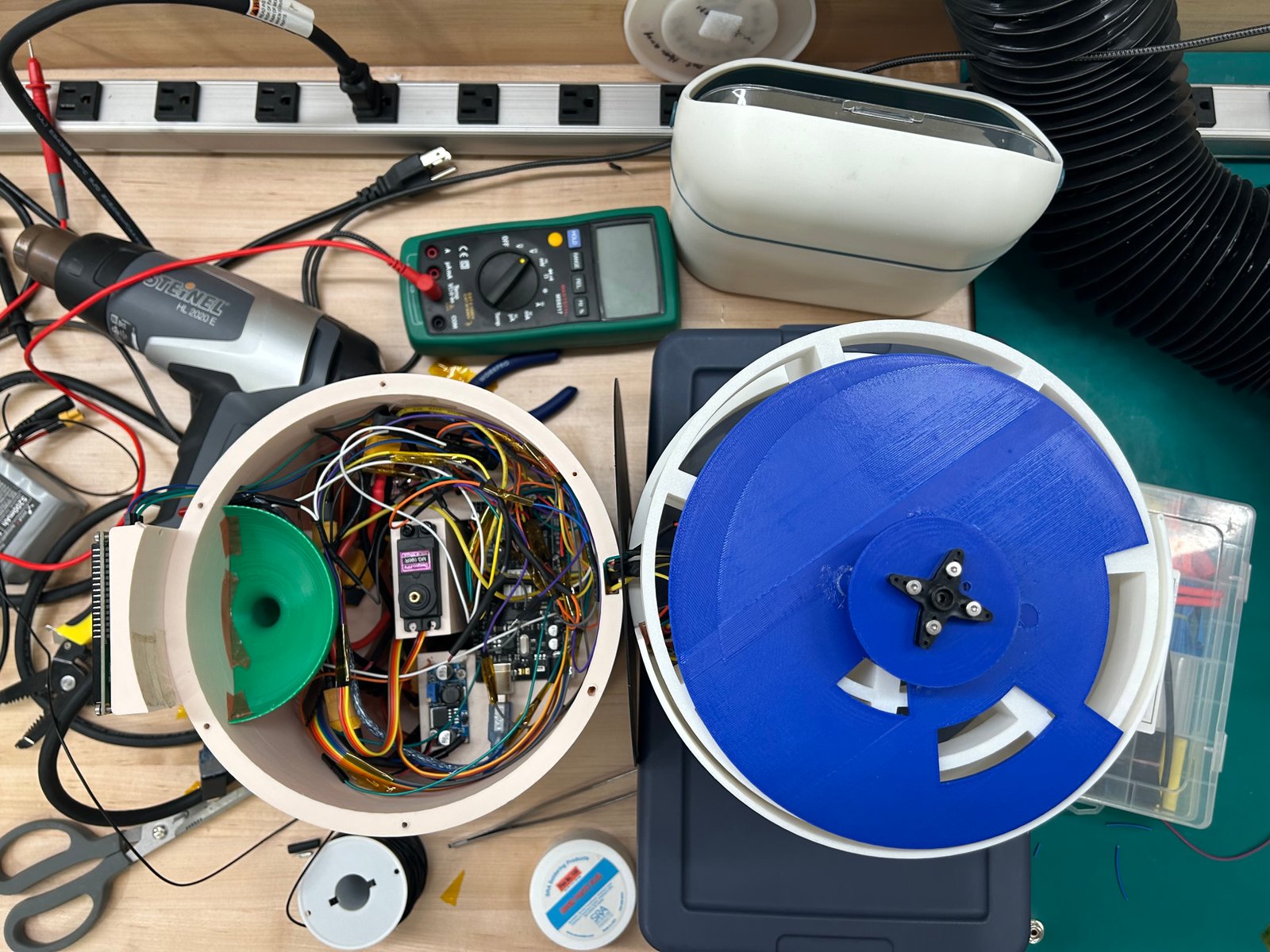

I used Fusion 360 to design and iterate the dispensing mechanism: a rotating carousel for compartmentalized storage, and a double rotary disk system to dispense pills down a funnel. CAD iterations emphasized alignment, smooth motion, and assembly access.

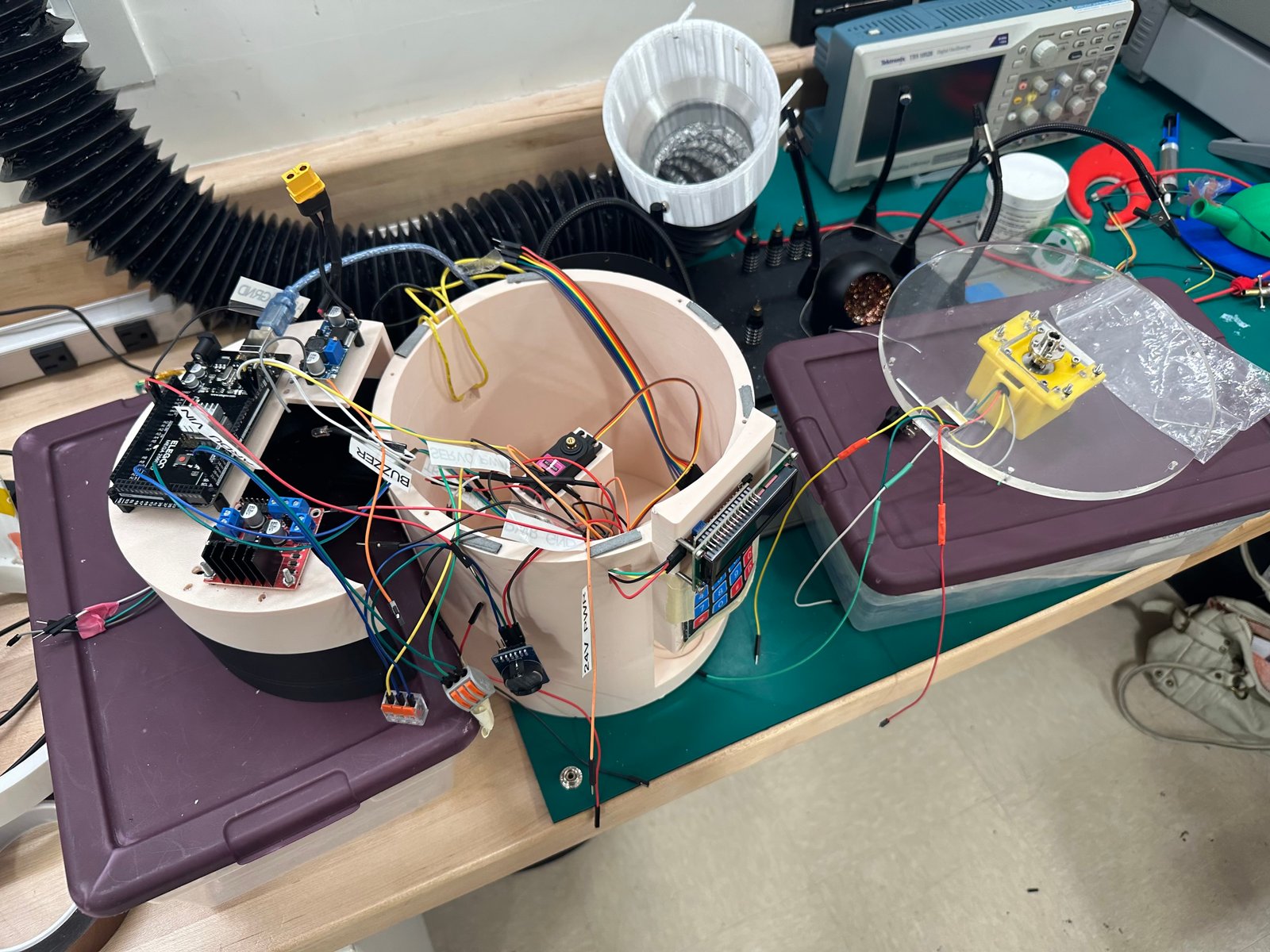

Electronics

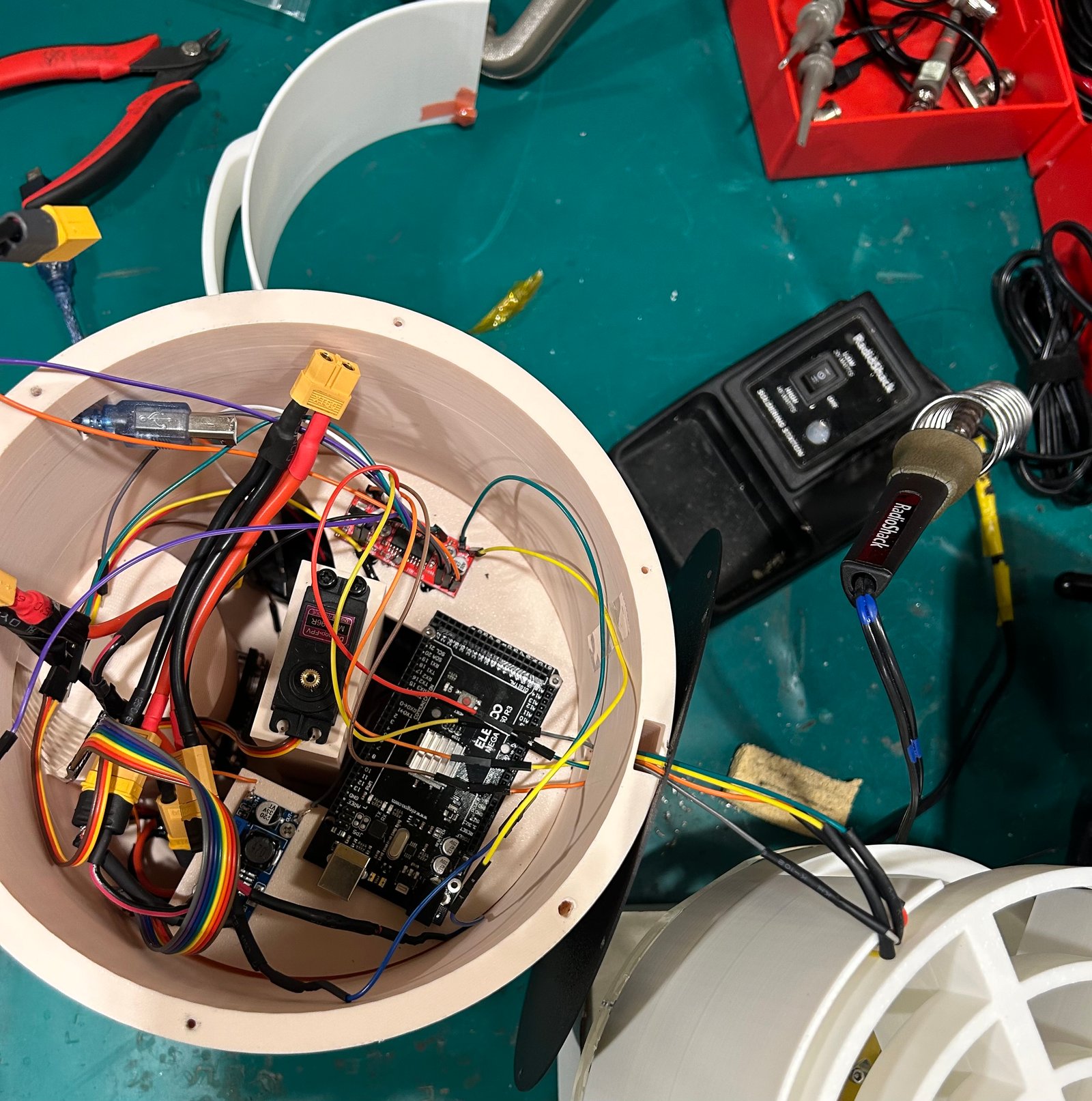

Control electronics include a microcontroller, display, speaker/buzzer, and motor drivers to coordinate reminders and actuation. The build reinforced the value of PCB-based integration for cleaner wiring, easier debugging, and a smaller, more reliable packaging footprint.

Components

Stepper + servo, motor drivers, regulators, ultrasonic sensor, keypad, display, audio output.

Next iteration

Move from loose wiring to a compact PCB + strain relief / connector retention.

Gallery

Build process and fabrication images.

Assembly

Manufacturing used 3D printing, laser cutting, manual-fed machinery, and power tools with PLA/ABS/acrylic. The project highlighted practical integration lessons: planning cable routing early, designing for serviceability, and prioritizing robust electrical connections.

Power

We used batteries + a switch, but a future iteration would prioritize outlet power for realism.

Reliability upgrades

Connector retention, cable locks for Dupont, and stronger mechanical indexing/magnet alignment.

Reflection

Challenges

• Debugging unorganized wiring + component placement constraints

• Dimensional/alignment issues in early prototypes → rapid fixes

• Coordinating LCD + RTC + keypad in one unified system

• Long lab nights under deadline pressure

What I learned

• More confident Fusion mechanical iteration

• Practical manufacturing + integration under constraints

• Why PCB integration improves reliability and packaging

by Justin Yu

by Justin Yu