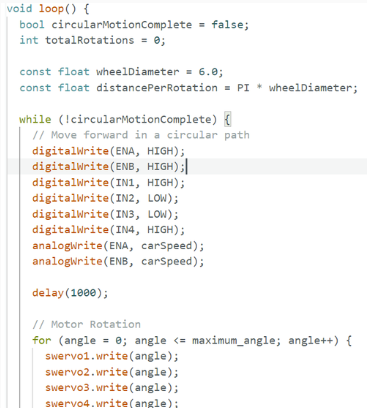

Overview

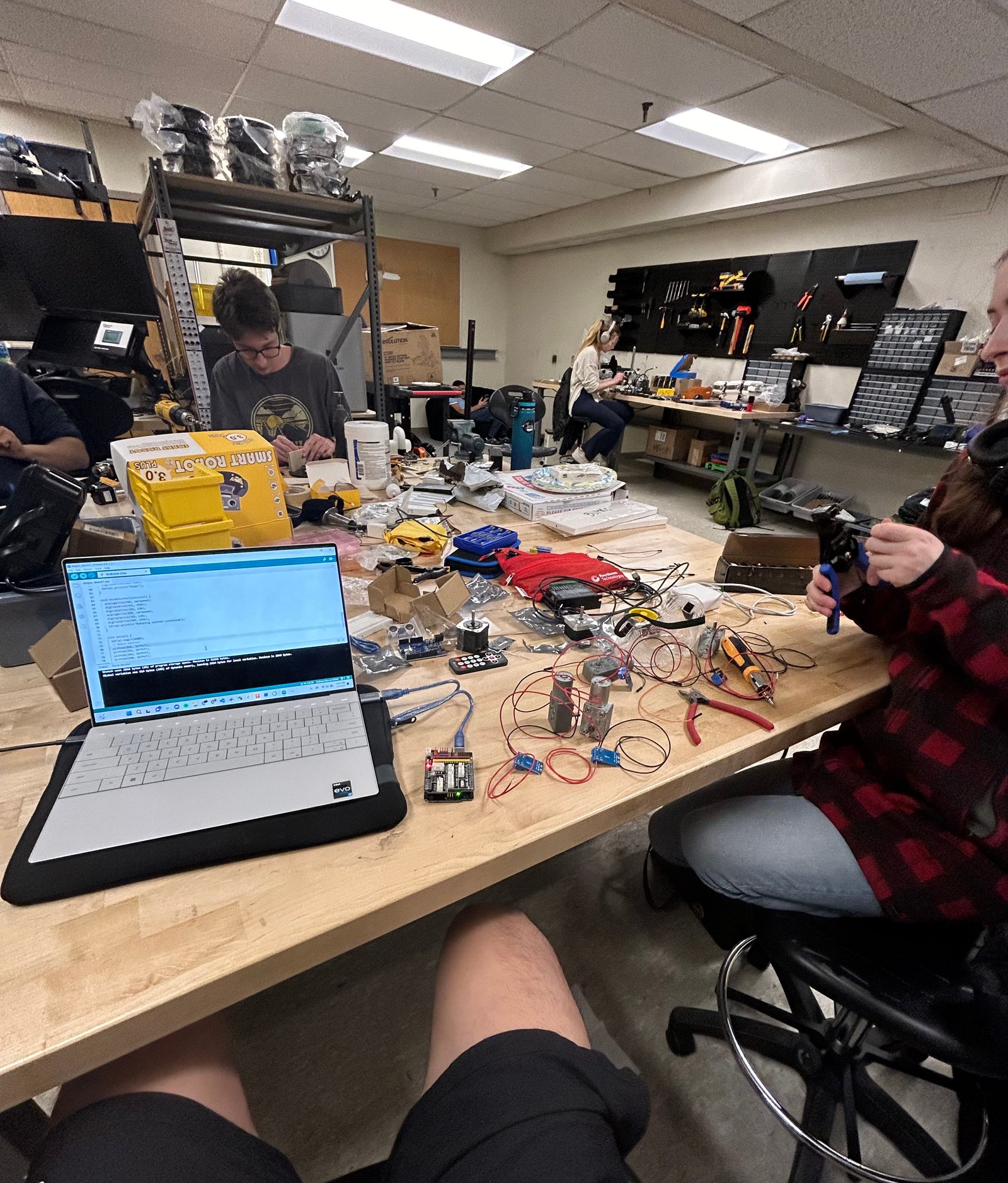

This event was held in collaboration with BU RASTIC and HackHardware to run a 24-hour robotics hackathon where teams built robots from provided kits (Elegoo Smart Robot Kits) and lab tools. My team (Charles Van Hook, Madeline Malloy, Ksenia Suglobova) intentionally deviated from the default kit chassis to build a more original rover aimed at durability, mobility, and adaptability to difficult terrains.

Tools & methods

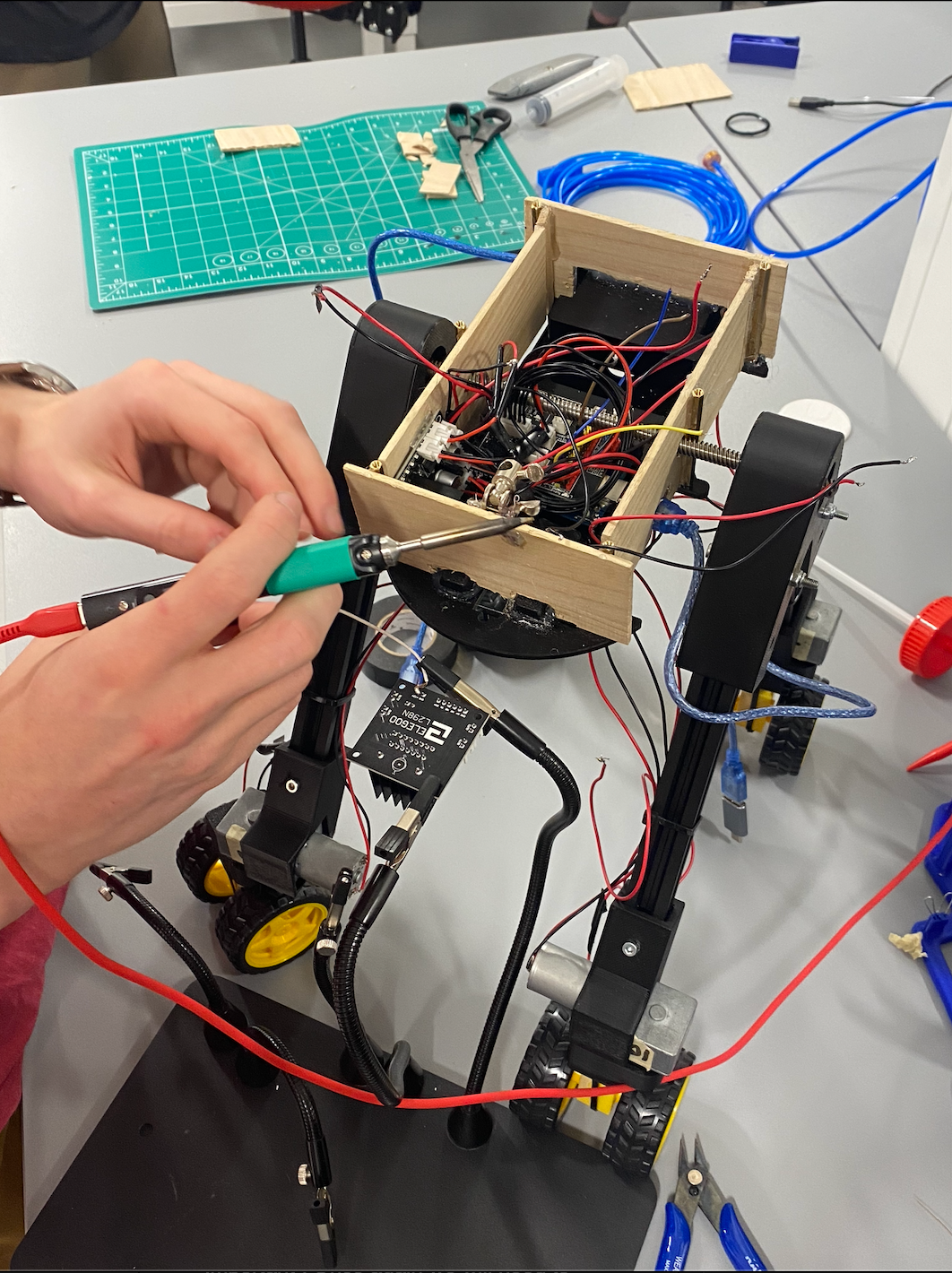

CAD (SolidWorks/Onshape), 3D printing, CNC machining, soldering, wiring & debugging, Arduino IDE/C++.

Hardware used

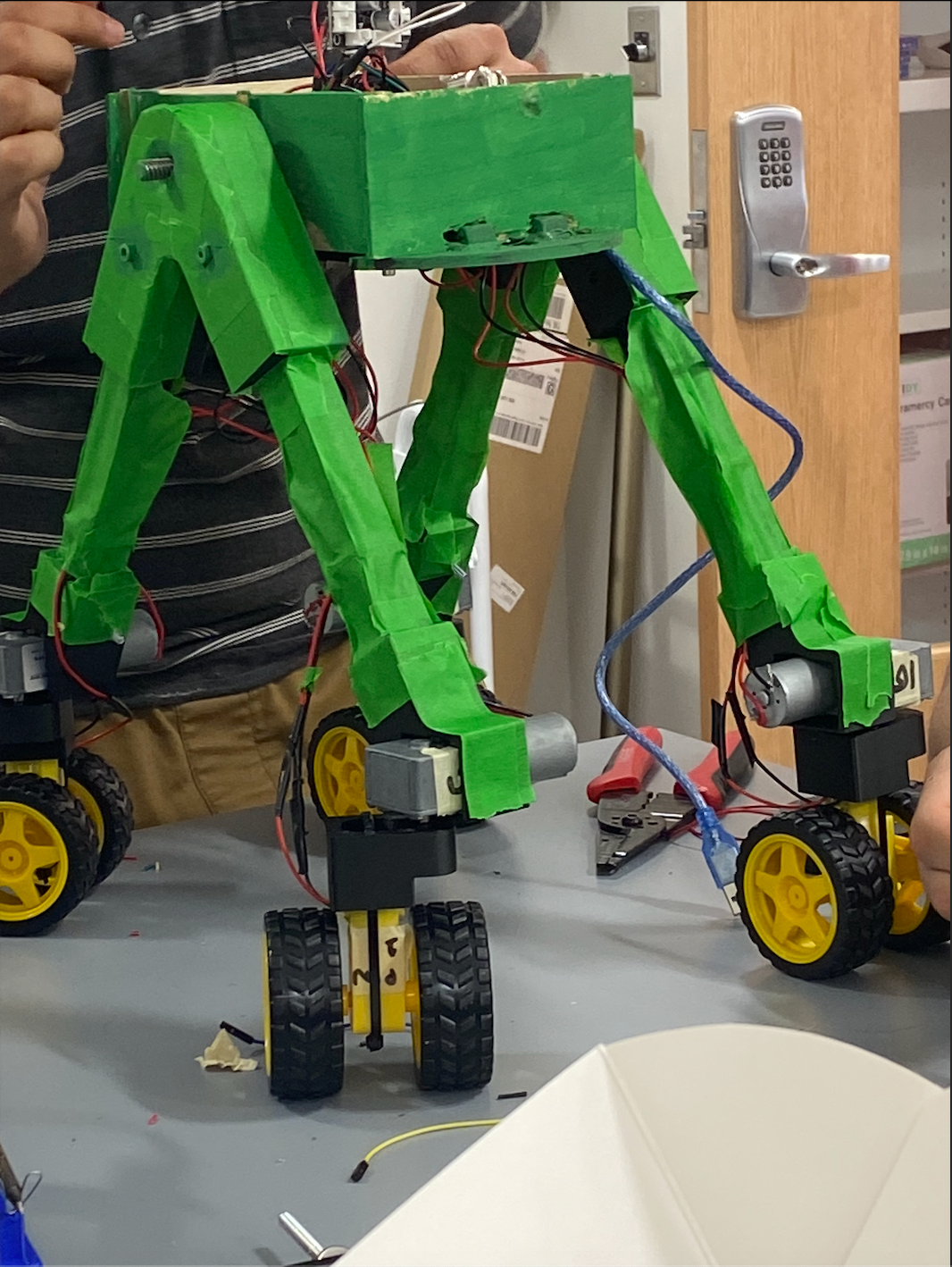

UNO controller + shields, relays, motor drivers, servo + stepper motors, power supply, Dupont wires, connectors, multimeters.

Design

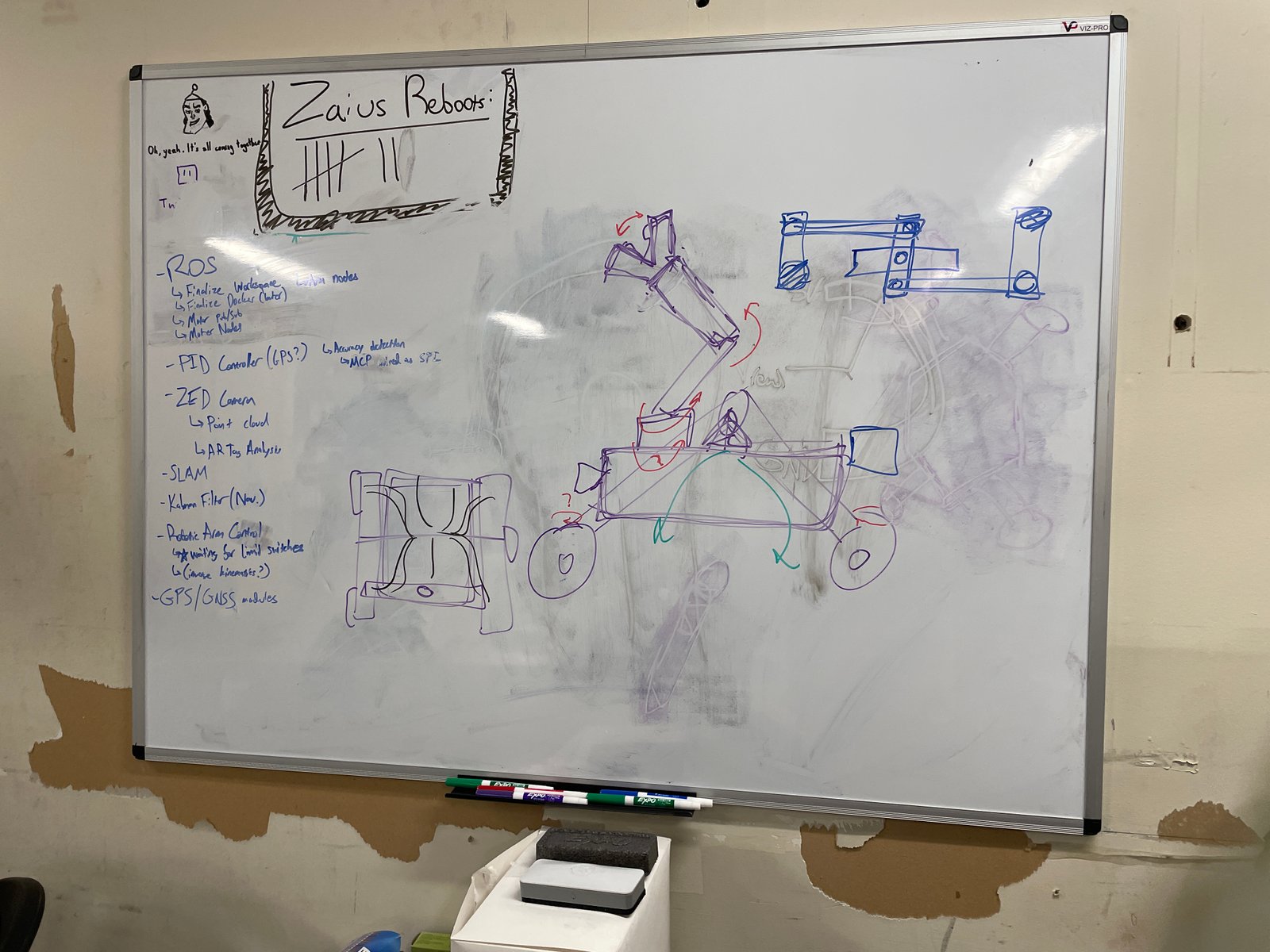

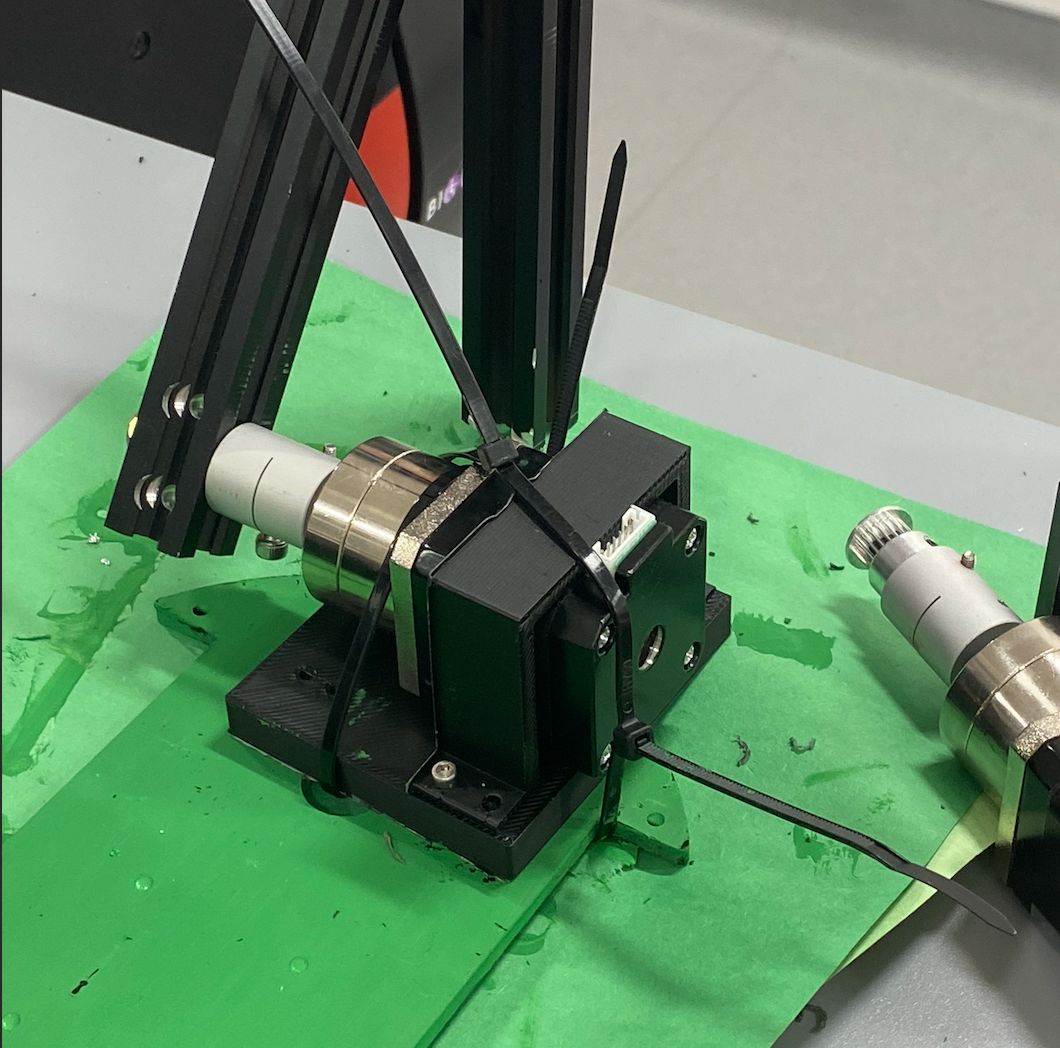

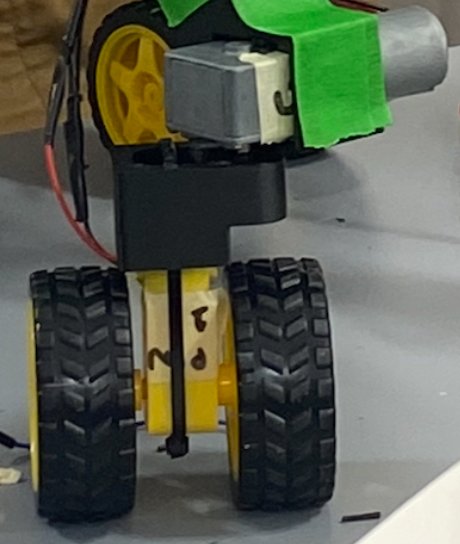

The chassis integrates wood boards and stainless steel sheets from the kit to house electrical components and manage circuitry. A V-shape suspension-like leg system improved stability and mobility, supplemented by a differential bar for balance. A servo-driven arm with a ball joint supported manipulation tasks. We also explored adding additional stepper motors to improve autonomy and turning capability.

Assembly

On day one, CAD finished for key attachments, but prints weren’t ready until the next morning. While prints ran, we crafted the chassis from wood and soldered connections to integrate additional motors/relays into the driver board’s PWM control. We couldn’t fully test code until the rover was assembled, and competition rules required autonomous motion (no controller).

Reflection

Challenges

• Circuit integration + debugging under time pressure

• Mechanical assembly with prints completing late

• Reliability: connections, mounting, and impact tolerance

• Staying in the lab past midnight and starving

What I learned

• Motor + driver fundamentals (servo vs stepper)

• Rapid iteration: build → test → fix → repeat

• Better wiring practices + cornercase handling

• Practical dimensioning to make parts “actually assemble”

by Justin Yu

by Justin Yu